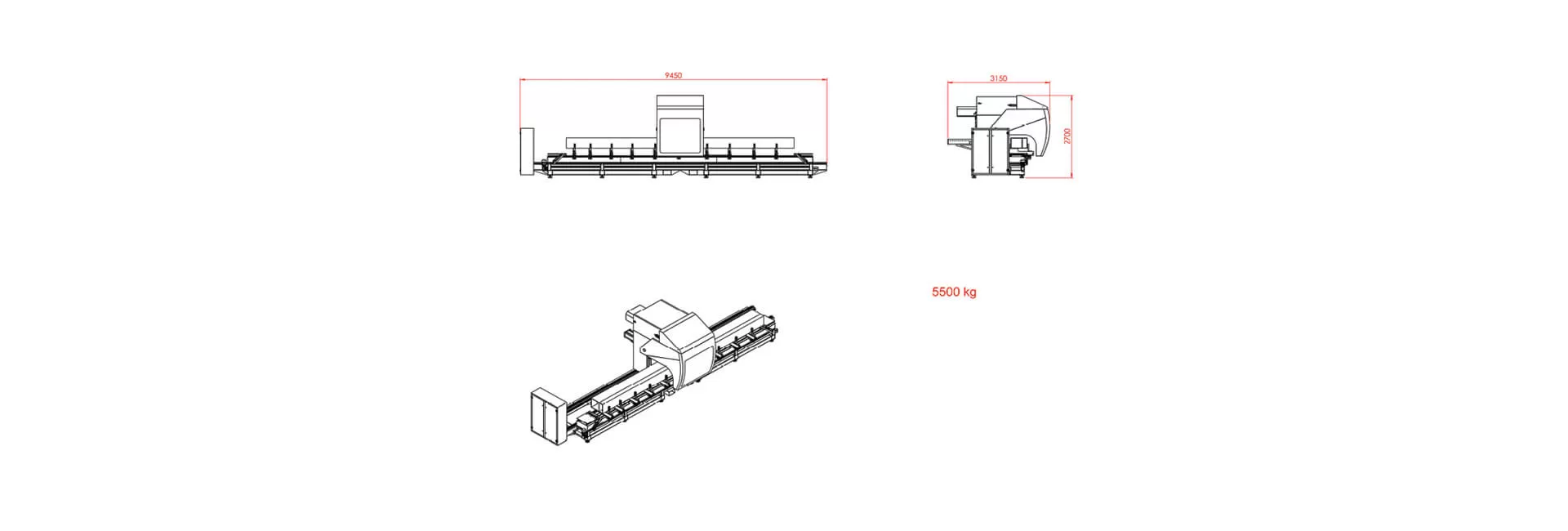

INO XP 9000 5 Axis CNC Profile Machining Center

Product Properties

ino XP 9000 is a real 5 axis CNC Profile Machining Center working on X-Y-Z-A-C axis independently.

Thanks to the CNC controller unit it is possible to make any routing, drilling, milling, notching and cutting operations on the profile pieces in any angle and any position.

The machine has a standard size of 7.5 meters and optionally 9.5 meters and 11.2 meters. The pneumatic profile holding clamps are moved by the C column itself and positioned according to the placed that are read from the Profile Machining Software to prevent from collision and for the best grip of the profile piece.

The Bi-Rotary head can tilt in A axis +/- 180 degrees and in C axis +/- 325 degrees with the spindle attached 12.0 kW 24.000 rpm with HSK-F63 tool holders.

The machine has a tool changer magazine of 10 positions and 1 for the notching and cutting blade. The blades that can be attached on the machine varies from 120 mm to 500 mm max. Thanks to the 500 mm notching blade it is possible to end mill or notch or cut any size of profile.

It is also possible to make the routing operations and the cutting operations in different angles on this machine.

Especially with the help of the “Profile MAchining Software” it is possible to list all the cutting and machining operations on the machine and carry them out on this machine without the need for another cutting machine.

The maximum profile processing sizes in 3 axis is 500X350 mm and in 5 axis 350 mm X 350 mm. There are 2 working zones on the machine for efficient use that can be extended to 4 different zones optionally.

Profile Machining Software

It works with customized software to process profiles.

Thanks to the Profile Processing Software, dxf drawings of the profiles to be processed are imported by the operator and displayed in 3D on the screen, the size of the profile to be processed is entered, each hole or slot or free shape is recorded as a macro, then these macros are introduced as operations to be performed on the profile; macros are selected and placed on the profile.

In case of the same operations in different profiles, the software parametrically places the same operations on profiles of different sizes and sizes, prepares the machining program by making all the calculations itself and can show these operations from the simulation screen.The machining programs performed are listed, profile orientation, 3D image, height, operations, customer information, etc. all appear in this list.The operator starts the machine by selecting the next operation from the list.

The profile processing software has been designed and developed in such a way that minimal work remains for the operator.Not only with the operator at the machine, but also in order to speed up the work, the office program is used in the office when it is desired to prepare a program for the machine.In the office version, the technician working in the office can easily prepare the processes as if he is next to the machine and see them on the simulation screen, not only prepare the processing programs, but also export information to the cutting machine by preparing an optimized cutting list according to the cutting lengths of the profiles to be processed.He extracts the barcode from the cutting machine, the machining center operator scans this barcode into the machining center and processes the profile.

Optionally, Orgadata prepares machining programs on machines by importing information from Schücal ReynaPRO and similar manufacturing software.By obtaining additional licenses for different machines within the enterprise, these processing programs can be operated and shared on other machines regardless of their brands.

Machining Dimensions

The profile processing length is 7,500 mm, it is possible to put and process 2 separate profiles up to 3,500 mm in two separate stations.

Profile processing dimensions are 500 mm. X 350 mm above and after the profile; when it is desired to process the profile from the top, back and front, it is 350 mm.X350 mm.A-axis movement: +/- 185 degrees. C-axis movement: +/- 320 degrees

Main Body

Welded steel frame normalized by heat treatment.The main body of the machine is machined in the 5-Axis CNC Steel Machining Center.

The entire body is painted with electrostatic powder paint.

Mostly all mechanical parts are machined in our own cnc machining centers or machined on cast material.

During the design process, our design team prioritizes the ease of use and ergonomics of the operators’ machines.In the mechanical structure, not only steel and aluminum are used; at the same time, fiberglass casting parts are also used to reduce the weight of the processing bridge and give the machine a more aesthetic appearance.

Tool Changer Magazine

It is a 9-pack and servo-controlled “Linear Type” magazine placed on the bridge of the machine.

The teams are placed side by side.While 9 milling cutters are in the same magazine, the second magazine integrated into the C column has a saw set of 500.The top of the magazine is closed with a protection cover made of pneumatically moving fiber material.The machine can change tools at its location without losing any time during operation.

Electrical Box and Controller Terminal

The electrical panel is positioned separately from the machine on wheels.Forced fan cooled as standard, optionally cooled by air conditioning for hot climates.The control terminal is also designed as a separate kiosk, it is connected to the electrical panel by a 5-meter cable.

The control terminal is also wheeled and can be positioned in the most convenient place for the operator around the machine.Thanks to this positioning, every point of the machine is easily accessible to the operator and can follow the machine from anywhere during machining.On the control terminal, there is an Industrial PC and its display, machine on/off button, buttons that move axes +/- , potentiometer buttons that manage the machine progress rate, as well as keyboard and mouse.

Axis features

With the help of X-axis Servo Motor and Planetary reducer, the crème movement on the teeth, pinions and linear slides.Axis speed is 90 m./min.With the help of Y-axis Servo Motor and Planetary reducer, the craveli movement on the tread, pinion and linear slides.Axis speed 65 m./minThe Z-axis moves with a 1/1 reduction coupling on a 25-roll 25 screw shaft.Axis speed 25 m./minThe A-Axis rotates with a gapless Harmonic reducer in a ratio of 1:120.The C-Axis rotates with a gapless Harmonic reducer in a ratio of 1:120.

Standard Equipment

Two pneumatic reference points.

8 pneumatic vise groups with manual positioning.12.0 kw 24,000 rpm HSK F-63 spindle and 10-pack tool changer magazine.

Openable machine protection cover.

Spray lubrication device.Lubrication of axis bearings.

3D CAD-CAM software.

19″ Intel PC + licensed Windows 10.

Optional Accessories

Automatic positioning of pneumatic vents.

Kerting saw and holder kit 500 mm.17 kW 24,000 rpm HSKF-63 spindle with holder.

10 sets of tool holders, pliers and nibs.

Transfer of information from window programs (Orgadata, etc.) with barcode reader.Chip evacuation conveyor.

Extra pneumatic vice.Electric cabinet air conditioner.

Related Products

Display AllCNC

MACHINE

TECHNOLOGIES

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review