INO CARRERA 4 Axis CNC Profile Machining & Cutting Center

Product Properties

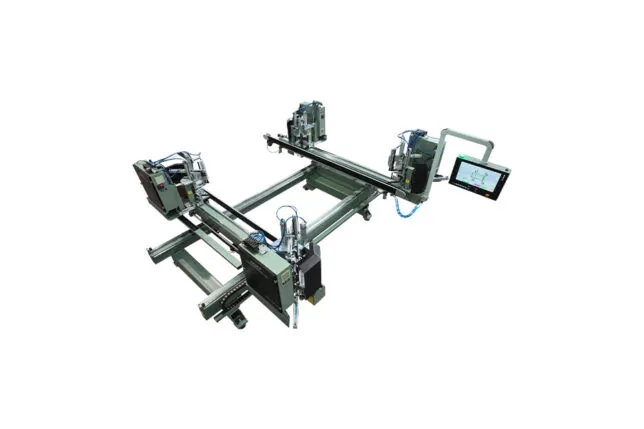

INO CARRERA is a Gantry type 4 axis CNC machining and cutting center for processing and cutting profiles. The Maxi-Steel type of extra strengthened machine body has a huge rigidity and flexibility in processing profiles up to 550 mm X 350 mm in 0,1 mm / 1 meter precision and 80 mt./min X Axis speed. With the heavy body and the gantry type of machining bridge, it is possible to process the heaviest aluminium profiles, even hard steel and stainless steel profiles.

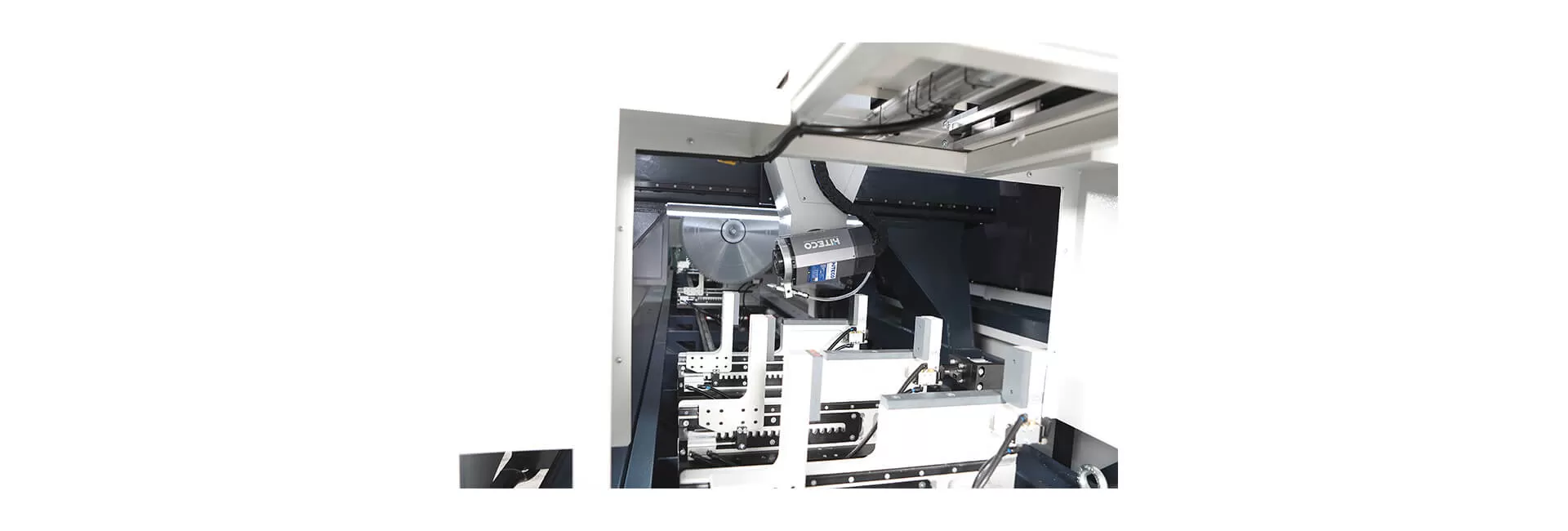

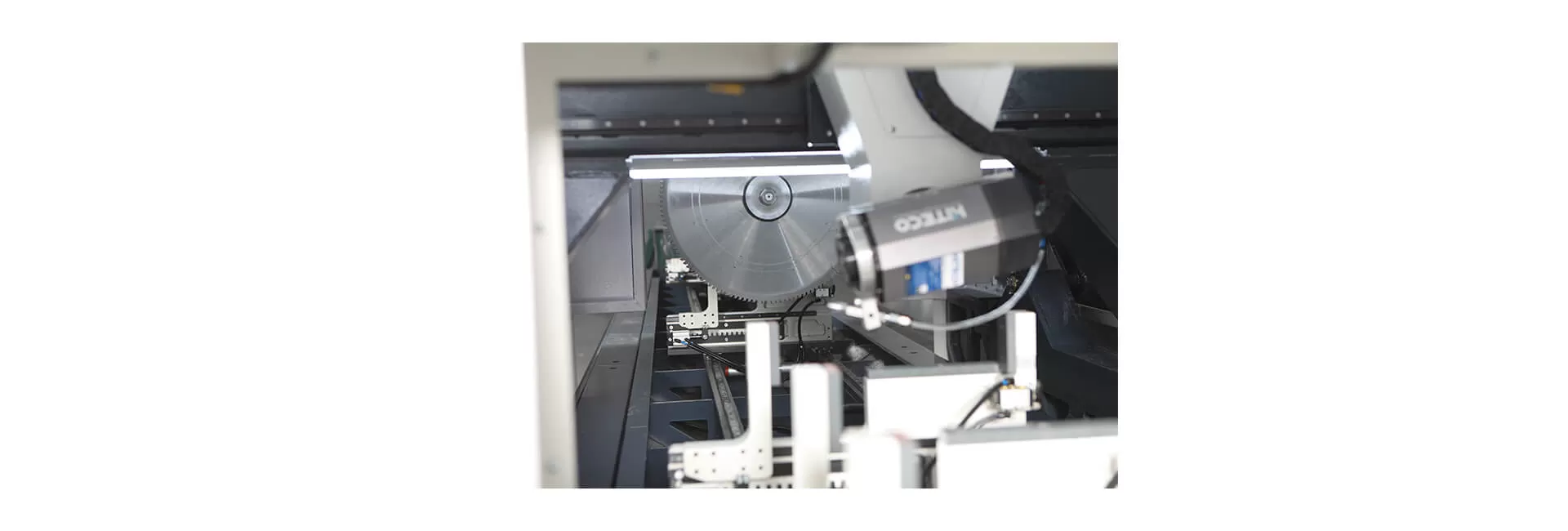

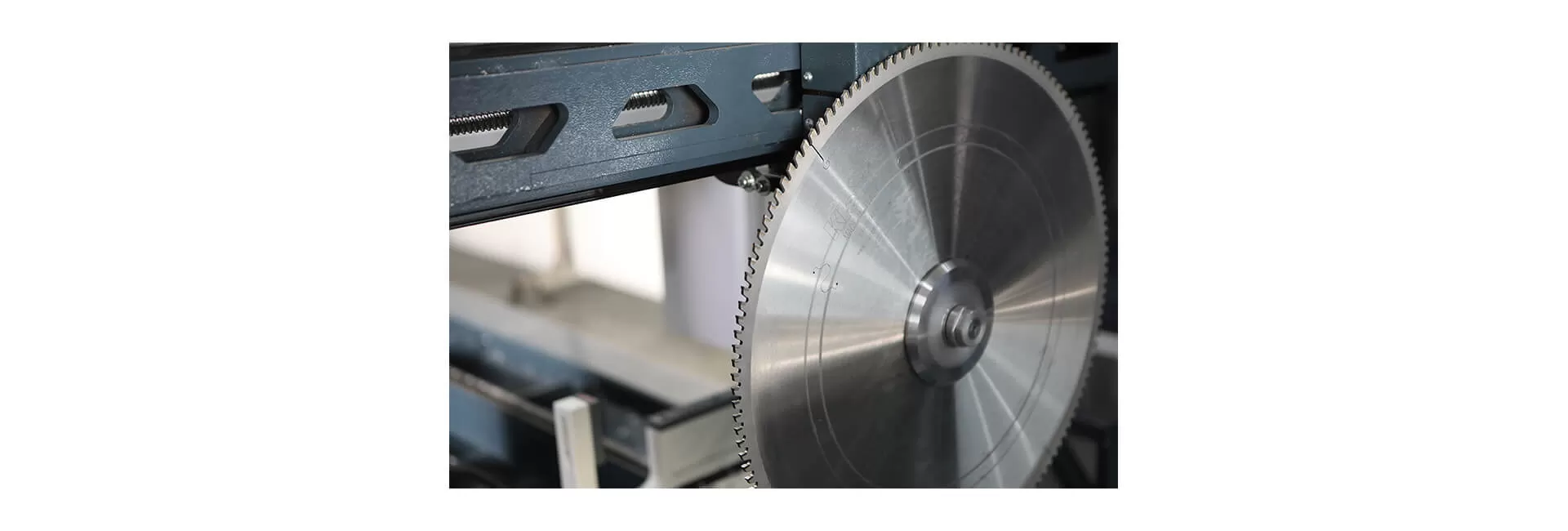

The cutting unit that is placed at the back of the bridge can cut the profiles into 90, 45 and 135 degrees automatically without moving the profiles away from the machine. The sawblade moves in a radial way to cut the profiles. This machine is designed especially for large sliding windows series that has large frame profiles to cut.

The clamping units are moved automatically by the column and the data is from the 3D CAD CAM profile machining software that generates G codes from the profile drawings. All profile data can be imported from dxf and dwg files very easily through the software and the machining operations can be programmed by using the ready macros for drilling and milling. The machine has 7.5 kW 24.000 rpm spindle with adjustable speed for different thickness of materials.

The high speed spindle can rotate in A axis between 0 and 180 in all intermediate degrees. All the axes are controlled by the brushless servo motors and servo drivers through CNC controller. The real CNC controller is collecting the processing data of G codes from the 3D CAD-CAM profile machining software and all the moves of the axes are adjusted very smoothly and controlled perfectly. The cutting sawblade has a diameter of 600 mm and its inclination into 45 and 135 degrees are maintained via pneumatic cylinders. Optionally, it is possible to make all in between degrees electronically controlled independent from the drive.

The automatic tool changer magazine with 10 positions is placed inside the machine cover right next to the spindle. The tool changer is moving with the spindle not to lose time during the tool changes. Inside the tool changer magazine, it is possible to place many tools up to 300 mm of disc cutter diameter and 200 mm length of cutter bits. This giant tooling helps the operator to solve many machining problems very easily. The ISO 30 conic toolholders are standard where in case the customer needs, HSK F63 is also possible optionally.

The tool length measurement technology is also placed inside the tool changer magazine, to measure the tools before the machining starts.

Thanks to the CNC controlled roller conveyor for extracting the dust caused by the machining procedures, all the swarf is carried out automatically.

Machine Dimensions

Machine net processing length is 8.500 mm. In 2 stations 4.250 mm. in each station is possible. Profile processing dimensions from the top, from the back and from the front 350 mm. X 350 mm. Profile cutting dimensions: 550 mm. X 200 mm.

Profile cutting dimesion in 90 degrees.: 550 mm. X 155 mm.

Profile cutting dimesion in 45 degrees.

550 mm. X 350 mm. Profile processing from the top and back

350 mm. X 350 mm. Profile processing in 4 Axis.

Profile cutting length in both sides 90 degrees: 7.900 mm.

Profile cutting length in both sides 45 degrees: 6.700 mm.

Profile Machining Software

The machine works with a customized software for processing profiles. Thanks to the Profile Processing Software, dxf drawings of the profiles to be processed are imported by the operator and displayed in 3D on the screen. The length of the profile is entered, each hole or slot or free shape is recorded as a macro, then these macros are introduced as the operations to be performed on the profile. These macros are selected and placed on the profile. In case the same operations shall be carried out on different profiles, the software will set the same operations parametrically on different length, prepare the machining program by making all calculations automatically and show the simulation of the machining. The processing programs are all listed on the HMI, profile orientation, 3D view, size, operations, customer information etc. all appear in this list.

The operator uses the machine by selecting the next operation on the list one by one. Profile processing software has been designed and developed as user friendly as possible to maintain the fastest training for the machine’s use. An office program is used in case it is desired to prepare machining files also in the office to speed up the work. In the office version, the technician working in the office can easily prepare the operations as if they were next to the machine and see the operations on the simulation screen. In the office version, the technician does not only prepare the processing programs, but also imports data for the cutting machine by preparing an optimized cut list according to the cutting lengths of the profiles to be processed. It produces barcodes from the cutting machine and the machining center operator reads this barcode to process the profile.

Optionally, it prepares the machining programs on the machines by importing information from Orgadata, Schücal ReynaPRO and similar manufacturing software. These softwares work with much higher efficiency when they use our Profile Processing Software to execute their output files. These processing programs can be run and shared on other machines regardless of their brands by obtaining additional licenses for different machines. With our Profile Processing Software, the company will have unlimited software abilities.

Machining Dimensions

Machine net processing length is 8.500 mm. In 2 stations 4.250 mm. in each station is possible. Profile processing dimensions from the top, from the back and from the front 350 mm. X 350 mm. Profile cutting dimensions: 550 mm. X 200 mm.

Profile cutting dimesion in 90 degrees.: 550 mm. X 155 mm.

Profile cutting dimesion in 45 degrees.

550 mm. X 350 mm. Profile processing from the top and back

350 mm. X 350 mm. Profile processing in 4 Axis.

Profile cutting length in both sides 90 degrees: 7.900 mm.

Profile cutting length in both sides 45 degrees: 6.700 mm.

Main Body

Electrowelded steel structure normalized with thermal treatment.

The main body of the machine is processed in 5 Axis CNC Steel Machining Center.

All the body is painted with powder coating.

Mostly all the mechanical pieces are die-casted and machined in our own cnc machining centers. During the design period, our design team prioritize the operators’ ease of use and ergonomy of the machines in the first place.

We don’t only use steel and aluminium in the mechanical structure; but we also use fiberglass casted pieces to decrease the weight of the machining bridge and give the machine a more esthetic look.

Spindles

The standard air cooling spindle has a power of 7,5 kW 24.000 rpm ISO 30 tooling and an automatic tool changer magazine of 10 positions. Thanks to the frequency inverter, it is possible to adjust the rpm between 0 and 24.000. Optionally, a liquid cooling spindle with 12,0 kW 24.000 rpm HSK F-63 tooling is also possible. Also, optionally it is possible to select an angular double sided spindle to process from the ends of the profiles. The sawing unit has a 3 kW belt driven motor and 2.800 rpm.

Tool Changer Magazine

Linear type magazine placed on the cover of the machine with 10 positions. 9 pieces of milling tools and one disc cutter are placed next to each other. The magazine is covered with a pneumatic moving protection cover that is made of fiber material to protect the tools from sawdust. Thanks to the opening sides of the machine cover, it is easy to reach the tools inside the magazine.

Electrical Box and Controller Terminal

There is a separate electrical box that is mostly placed at the back of the machine with wheels under the cabinet. Plus there is a user terminal also with wheels and with a PC on it; connected to the electrical cabinet via 1 Ethernet cable that has a length of 5 meters. The operator can move the user terminal independently. Optionally, it is possible to connect A/C on the electrics box. On the user terminal, there are keyboard, mouse, handwheel and a button set composed of on/off button, start button, axis moving buttons, feed rate regulator and emergency button.

Axis features

2 pieces X-Axis – servo motors + planetary gearbox – moving on helical rack and pinion that is supported by linear guides. Axis speed 80 m./min.

Y- Axis – servo motor + planetary gearbox – moving on helical rack and pinion that is supported by linear guides. Axis speed 60 m./min.

Z- Axis – servo motor – moving on screw mill with a diameter of 20 mm and 20 pitch geared by coupling 1/1 ratio. Axis speed 25 m./min.

A- Axis – servo motor – moving on harmonic gear with 1:120 ratio, Nominal Torque of the reducer is 480 Nm.

B- Axis – servo motor (sawblade feed) + planetary gearbox – moving on helical rack and pinion that is supported by linear guides. Axis speed 40 m./min.

Standard Equipment

Double station working with double laser safety barriers.

8 pieces Manually positioned profile clamps. The width of the clamps are adjustable and they are also suitible for fixture connection.

Second stopper in the middle of the machine for the second station.

7,5 kw 24.000 rpm ISO 30 high speed spindle has an automatic tool changer magazine with 10 positions placed inside the cover of the machine.

Pulse spray mist coolant system.

3D CAD-CAM software Uni_Link.

Automatic tool length measurement device.

21.5” TouchPanel Intel PC with licanced Windows10.

Optional Accessories

Cutting Sawblade inclination in 45 and 135 degrees + all in between degrees between 45 and 135 HSK F-63 toolholder modification for the standard spindle.

Automatic positioning of the clamps moved by the bridge.

Disc cutter, 300 mm.

Data import with barcode reader from production softwares.

Wide Clamp modification for processing 550 mm width of profiles.

10,0 kW high speed spindle.

HSK F63 toolholders.

Tapping via thread milling with spacial tooling.

2 Extra clamps.

Air-conditioning unit.

Extra office software and profile cutting optimization for double mitre saws.

Data import from double mitre saws to the machining center via barcode.

Profile cutting data and profile machining data import from window production softwares like Orgadata and Schücal.

Related Products

Display AllALU

PROCESSING

MACHINES

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review