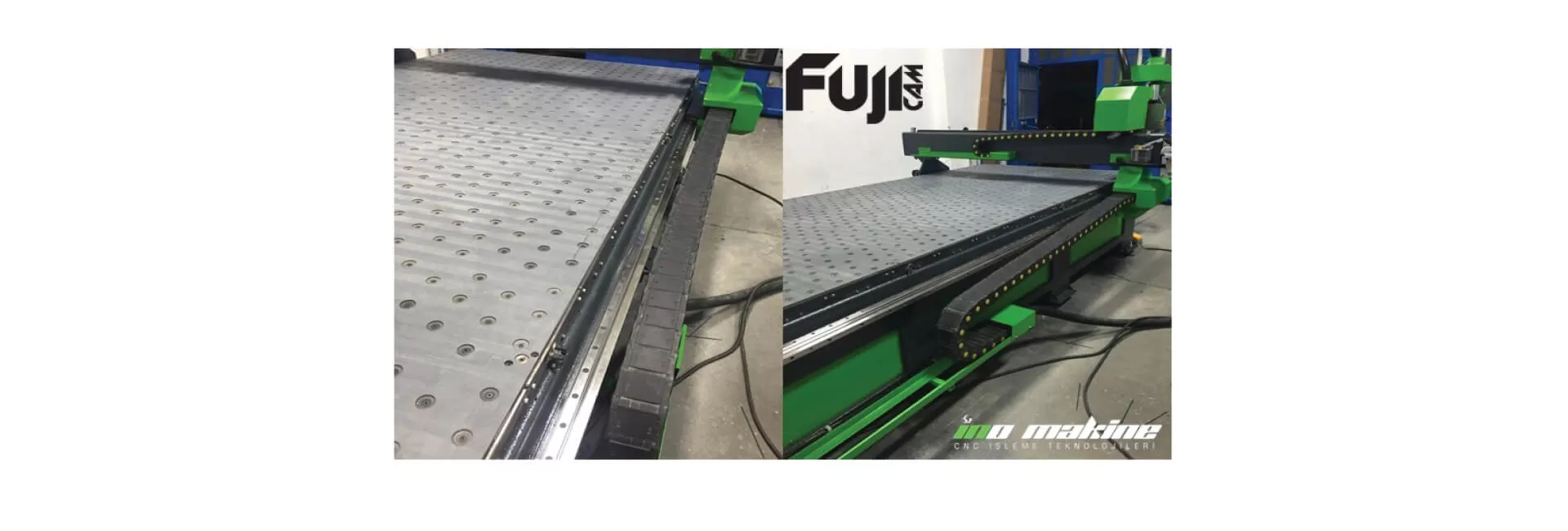

XA 1535 2nd Hand CNC Composite Machining Center

Product Properties

Ino XA 1535 (2nd Hand) is the most modern and modern facility that works in panel cutting and processing, especially facades manufacturing and application, and workshops that do contract cnc cutting – sizing, can process all kinds of plates – top grade aluminum composite panels up to 3.500 mm. it is the most economical double spindle CNC Panel Processing Center.

With this type of CNC composite machining center, we provide our customers with the optional CAD-CAM program, which is normally paid as an option, with the XA 1535 as standard – free of charge.

In addition, a set of joint and milling blades are delivered with the machine as a set.

Related Products

Display AllALU

PROCESSING

MACHINES

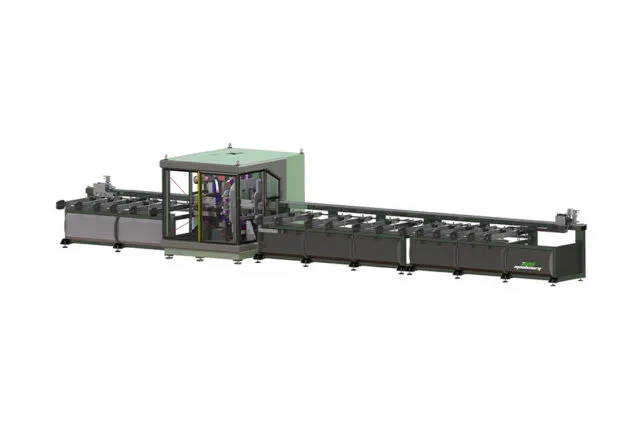

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

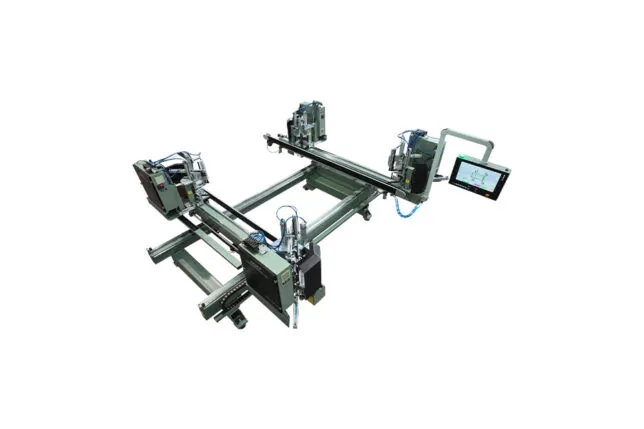

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review