AS 534 65 Double Mitre Saw with Radial Feed

Product Properties

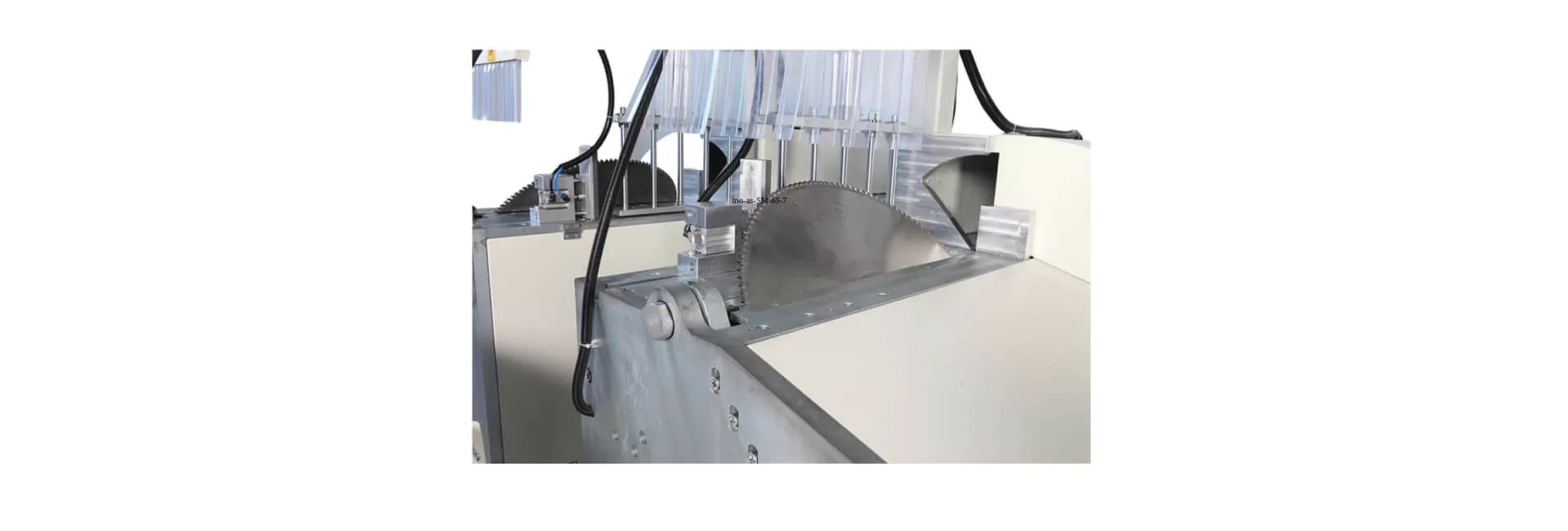

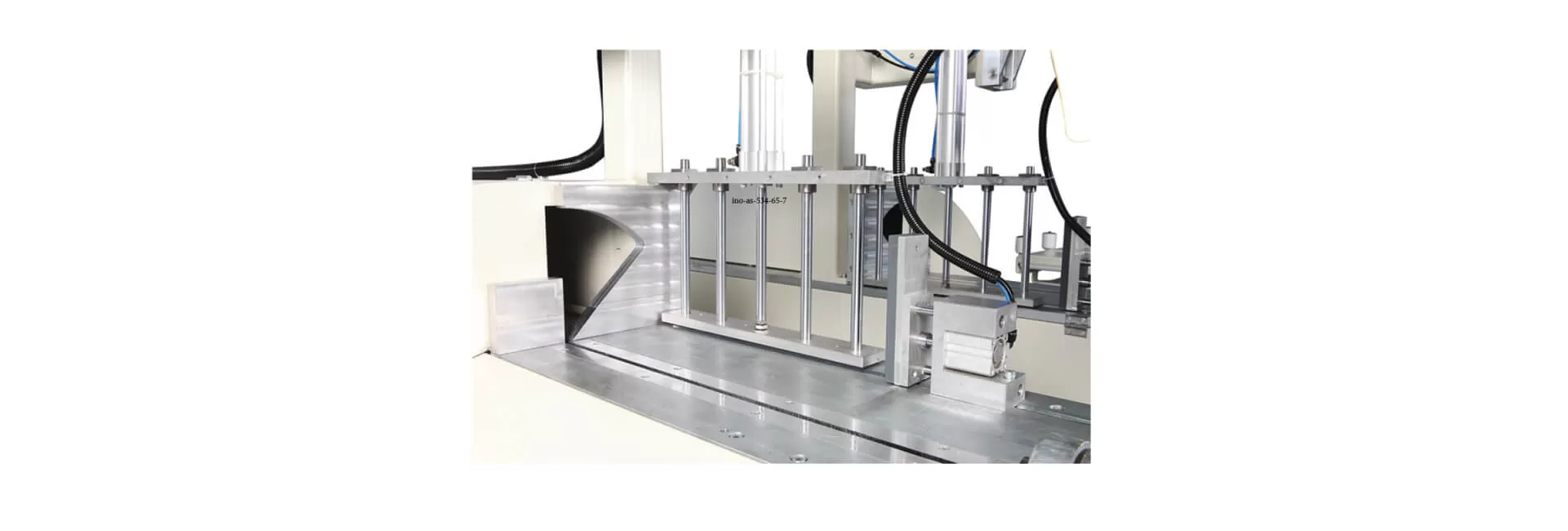

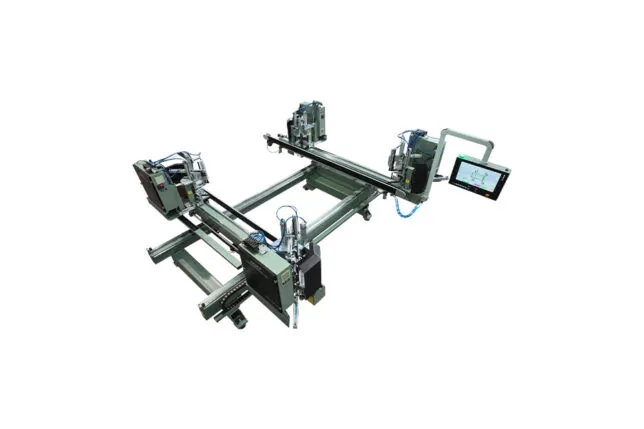

CNC controlled double-head cutting machine with 600 mm diameter Radial walking saw mechanism special for large aluminum profiles.

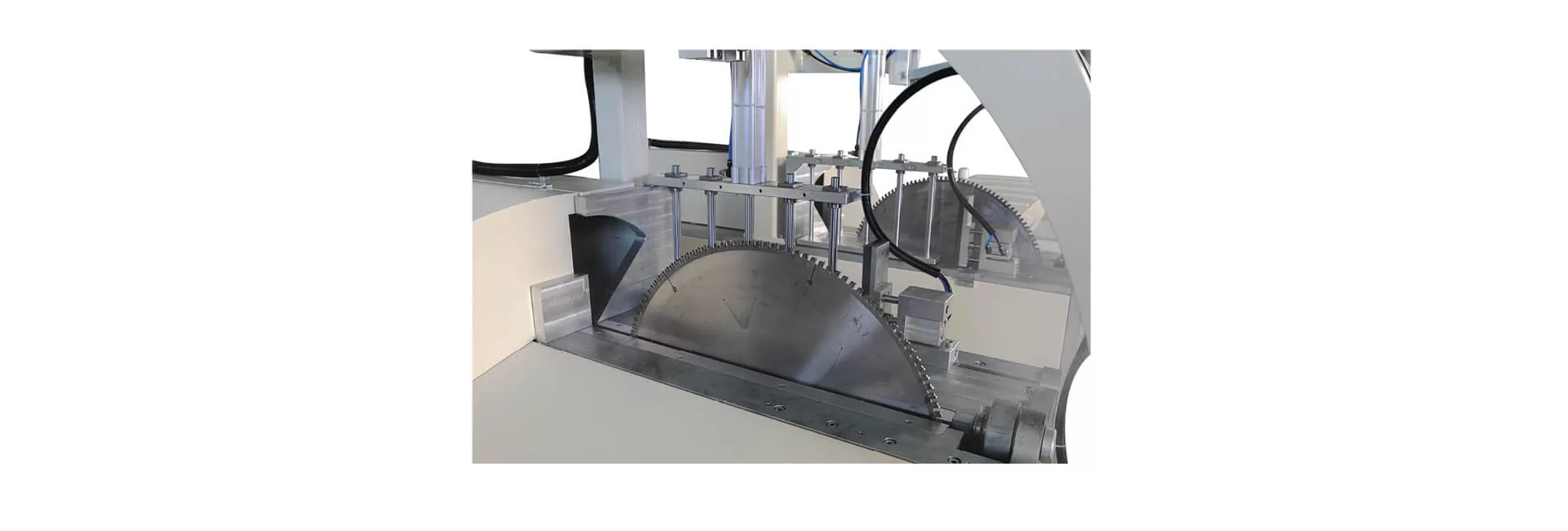

Precise cutting of profiles from both heads at the same time by opening the heads inwards and disposing of the saws at the same time. It is specially designed for cutting the case profiles of large industrial profiles with a profile width of up to 650 mm, wide sliding series profiles, hebessibe series, 3-rail and wide sliding with mosquito nets at 45 degrees.

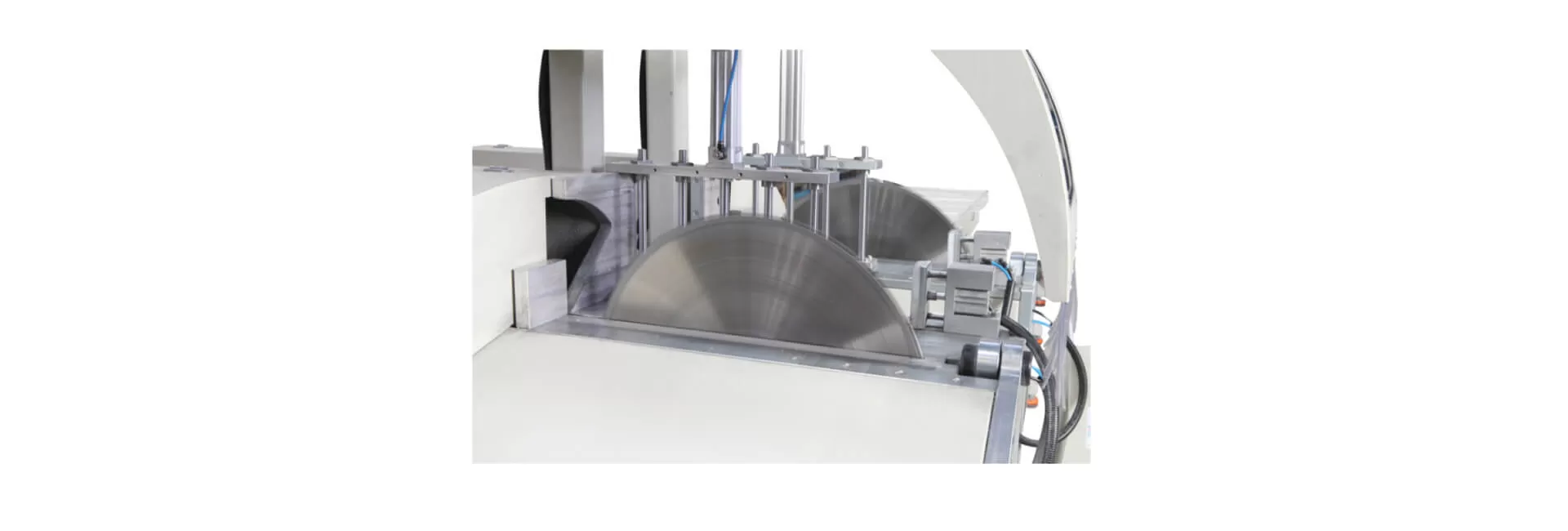

Two saws with a diameter of 600 mm are cooled by a spray lubrication unit.The heads can tilt 90 degrees and inward to 45 degrees.

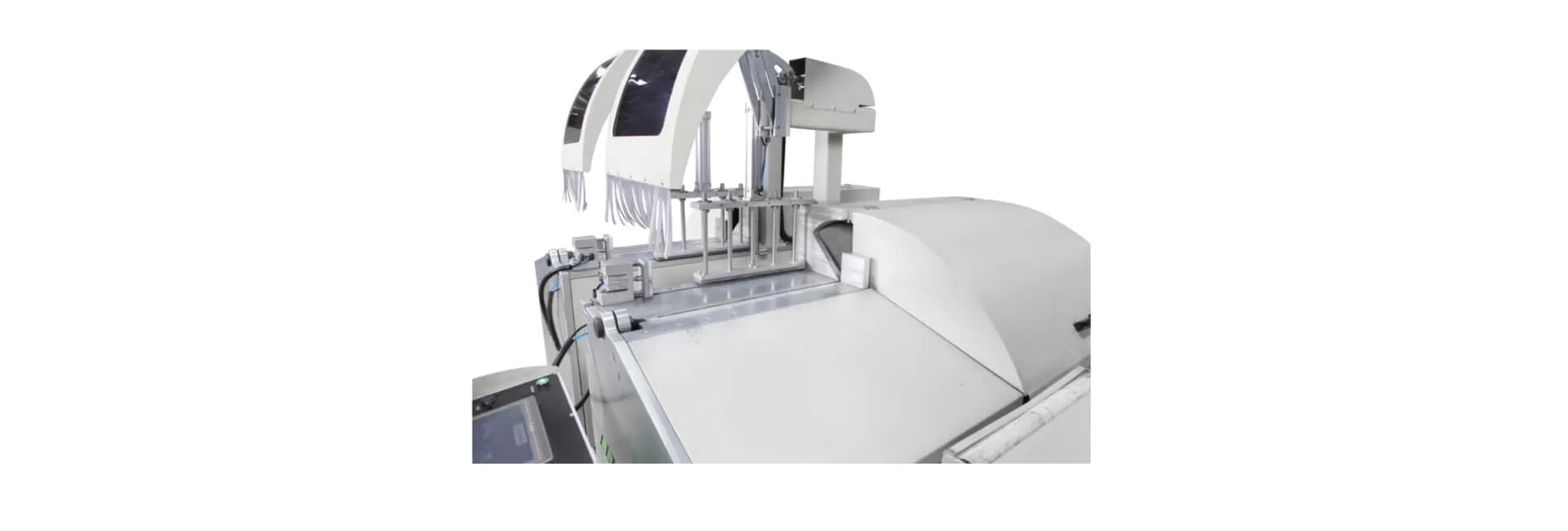

With hydropneumatic drive, walking saw mechanism.Thanks to the industrial computer with 10.2″ touch TFT-LCD screen, the control of the machine has been simplified to the utmost, and the use of menus such as entering cut lists, pulling optimization lists from optimization programs has been made user-friendly.

Profile Machining Software

A profile cutting control software is operated on the machine via a touch panel.

The machine is operated by entering the profile length and cutting angles to be cut on the screen.

It is possible to import data from window manufacturing programs into the machine in .csv format via USB or LAN cable or Wi-Fi, to cut through the list and to print barcodes on each cut profile.

Thanks to the profile processing software special to Ino Makine, it is possible to combine the cutting machines with the machining centers and to communicate the machines of different brands with each other.

Machining Dimensions

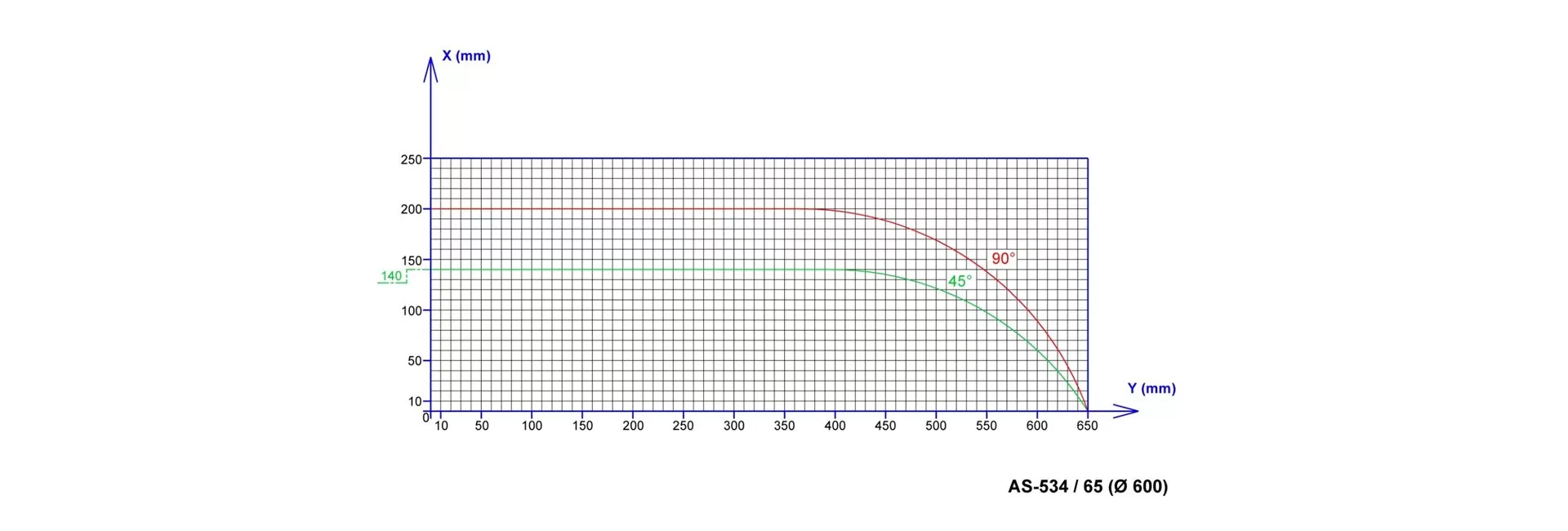

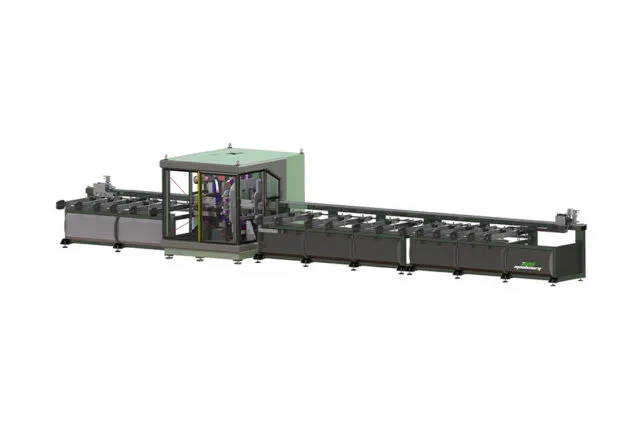

The machine, which has a net cut length of 6,500 mm, can size profiles up to 12,000 mm in length with software support.According to the cutting diagram, the cutting height is 200 mm, the cutting width is 650 mm.The largest cutting size according to the cutting diagram is at 45 degrees: 140 X 410 mm.The largest cutting size according to the cutting diagram is at 90 degrees: 200 X 380 mm.The net cut size at 90 degrees when the two heads are close to each other: 500 mm.The net cut measure of the two heads at 45 degrees inward when they are approached: 500 mm.

Main Body

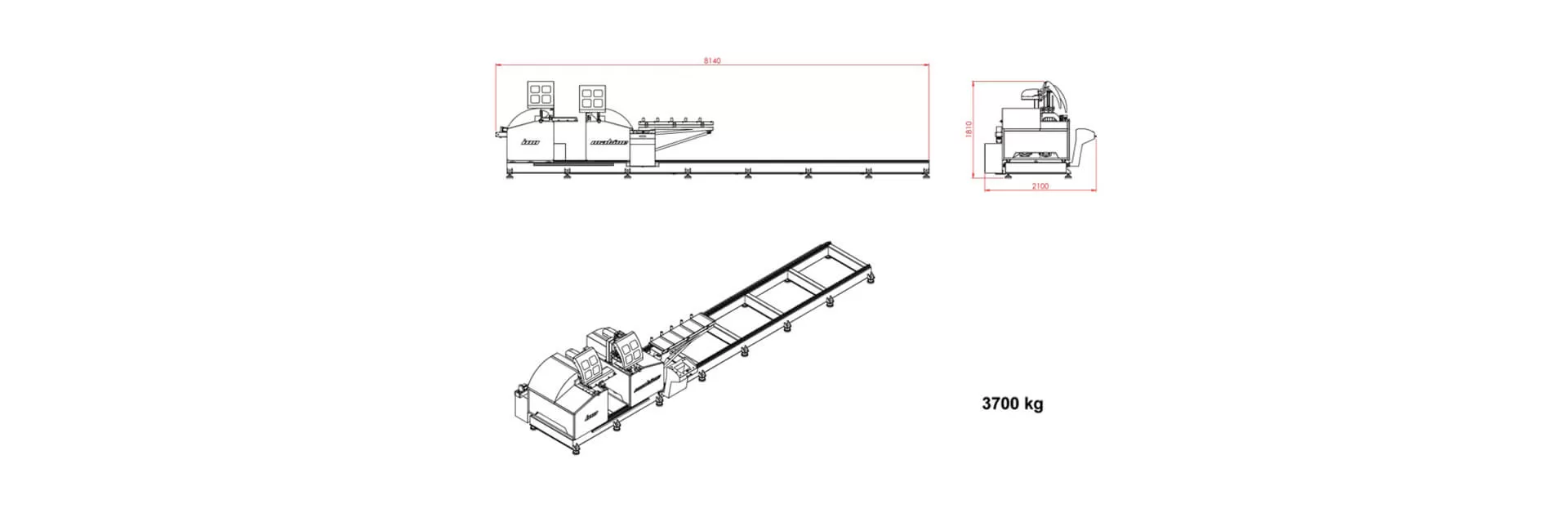

Welded steel frame normalized by heat treatment.The main body of the machine is machined in the 5-Axis CNC Steel Machining Center.

The entire body is painted with electrostatic powder paint.Mostly all mechanical parts are machined in our own cnc machining centers or machined on cast material.

During the design process, our design team prioritizes the ease of use and ergonomics of the operators’ machines.In the mechanical structure, not only steel and aluminum are used; at the same time, fiberglass casting parts are also used to reduce the weight of the processing bridge and give the machine a more aesthetic appearance.

Axis features

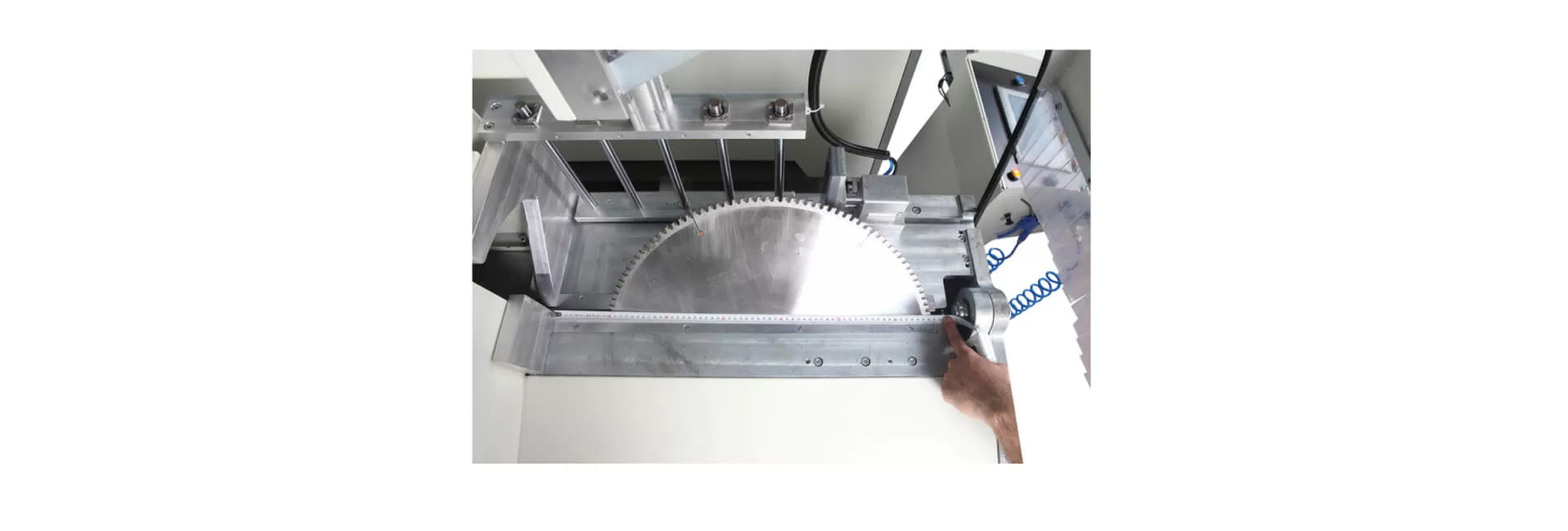

The second head movement is achieved by moving the pinion on the worm gear helical crazier with the geared servo motor and servo drive and pushing the head on linear sliders, reaching an accuracy of 0.1 mm. / 1 m in the cutting dimensions.90 degrees and 45 degrees inward are automatically adjusted from the control panel.

Standard Equipment

10.2″ TFT-LCD Touch panel.PLC Control system + 99999 pcs cutting memory.600 mm saws.4.0 kW 3,000 rpm saw motors.

Automatic cooling of saws with a spray lubrication unit.

Very clean cutting surface with radial (walking) saw movement and hydropneumatic feeding mechanism.

Automatic impingement of the cutting heads pneumatically to 45-90 degrees.

Slicing of aluminum profiles with automatic feed cutting feature.

Auto-descending shield protection covers on both heads.2 horizontal and 1 vertical profile compression unit.

Manual profile support unit – 4 pcs.Conveyor connected to the moving head.

Optional Accessories

Data transfer from window manufacturing programs.

The order and dimensions of the profiles to be cut by prescription cutting are pre-programmed and loaded into the machine.

Ability to add drives to saw motors and adjust saw speeds from the touch panel between 500-3,000 rpm.

Support conveyor to fixed head.

Barcode printing unit.

15″ Touch HMI panel.

Related Products

Display AllALU

PROCESSING

MACHINES

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review