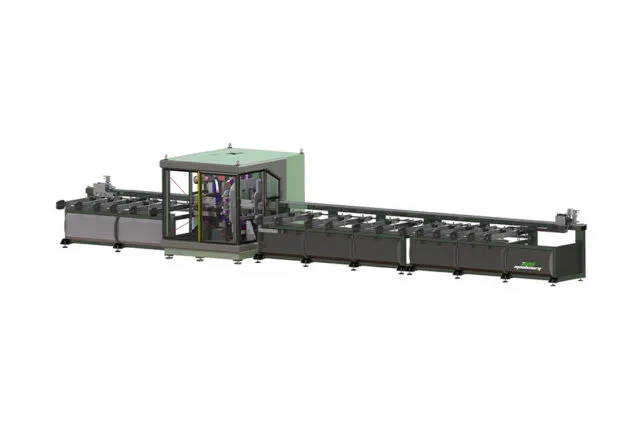

TESLA 61 Inside Outside Tilting Double Mitre Saw

ALU DOUBLE MITER SAW

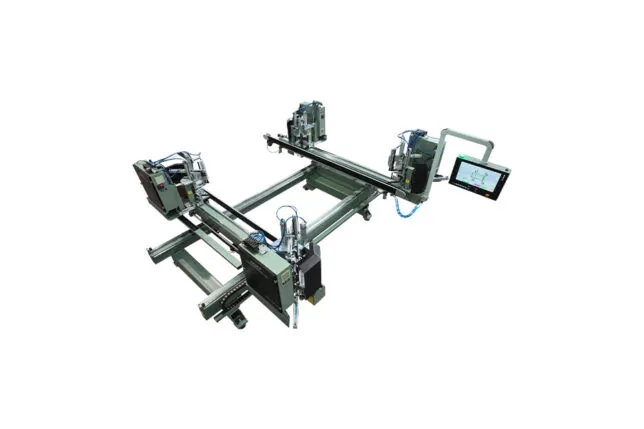

3 AXIS CNCIno Machinery’s new explanatory video for its 3 axis Saw.

The machine has 600 mm diameter diamond saws with a cutting width of 222 mm and a height of 325 mm.

Thanks to the CNC motion controller and harmonic drives, the positioning accuracy of the cutting length is 0.1 mm and the accuracy of the inclanation of the heads is 0.1 second.

The machine has a net cutting length of 6 meters and with software support it is possible to cut up to 9.7 meter profiles.

The controller can read any .csv file from window production softwares like Orgadata, Schucal or Chakal or similar.

Product Properties

Double Mitre Saw with 600 mm sawblades and 6 meter cutting length; customized for aluminium profiles. Second head moving on linear guides via rack&pinion and servo drives. Both heads tilting inside 45 to outside 22.5 adjusted electronically through servo motors and harmonic reducers. The advanced reducer technology that we use on this mechanism allows the servo motors work with zero backlash and maintain the most precise angular adjustment. Thanks to the fixed roller conveyor mounted on the secondary head and the manual supports, the profiles are placed on the machine easily and cut perfectly.

Profile Machining Software

The machine is controlled via a real 3-Axis CNC Controller + Intel i5 PC with 8 GB RAM 256 SSID and a touch panel TFT-LCD 24.0″ Screen.

The cutting dimension and the cutting degrees are entered to the machine by using this controller interface that is available in 8 different languages.

As the geometry of the cut changes depending on the height of the profile while cutting with both heads tilted inside and outside, the complexed trigonometric formulas are operating perfectly thanks to the CNC Controller.

It is possible to enter a cutting-list to the machine manually, or it is also possible to load cutting-lists via USB drive or LAN connection.

In this way, the machine can import any data from any window production software.

Thanks to the INO’s dedicated software, the machine can read all kinds of .csv or .txt files and produce labels for each cut piece.

Then those labels are read by the barcode reader of the CNC machining center and all the routing operations are identified without using any drawing software.

In this kind of CNC Controller it is possible to get connected to the machine over internet connection and troubleshoot easily.

Machining Dimensions

Main Body

Electrowelded steel structure normalized with thermal treatment.

The main body of the machine is processed in 5 Axis CNC Steel Machining Center.

All the body is painted with powder coating.

Mostly all the mechanical pieces are die-casted and machined in our own cnc machining centers.

During the design period, our design team prioritize the operators’ ease of use and ergonomy of the machines in the first place.

We don’t only use steel and aluminium in the mechanical structure; but we also use fiberglass casted pieces to decrease the weight of the machining bridge and give the machine a more esthetic look.

Electrical Box and Controller Terminal

The electrics box is welded on the beginning of the machine body. The controller terminal is also connected to the machine and it is movable according to the ease of use. The operator can reach all the buttons, the touch panel and place the profile by standing close to the controller terminal.

Standard Equipment

2 pieces 600 mm sawblades.

Automatically moving safety covers.

22.5-135 electronically inside and outside tilting cutting heads.

2 pices horizontal profile clamping pistons.

Manual support 1 piece.

Extended cut for cutting longer than 6 meter profiles.

Roller conveyor on the movable head.

3-Axis real CNC Controller + Intel PC + 24″ Touch-Screen.

Windows 10 operating system.

Pulse spray mist coolant system.

Cut-list programming manually.

Data import via USB.

Data import via wireless network connection.

Optional Accessories

2 pieces vertical clamping pistons.

Air-conditioning unit automatic feed cutting for corner cleats.

Protection shield with buttons integrated on.

Dust extraction roller conveyor.

Label Printer.

Importing data from window manufacturing softwares.

LAN connection for data import.

Free programmable CNC cutting system with automatic inside-outside tilting to different degrees and feeding different dimensions for any kind of small piece cutting.

Related Products

Display AllALU

PROCESSING

MACHINES

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review