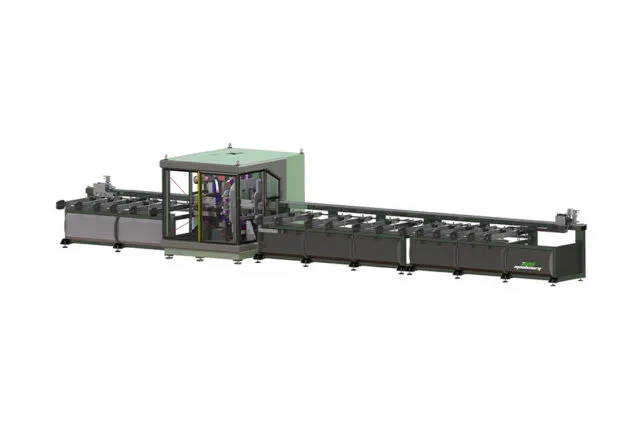

MES 1500 Electronic Measurement System

ALU

Digital Measurement SystemOur Digital Measurement System has a positioning system working with a servo motor. This equipment has a working tolerance of 0.1 mm and can be adapted to all kinds of single miter saws, double miter saws, and similar cutting machines. Thanks to the 10.2” TouchPanel and the plc, all window production software can be used on this equipment. The data is transferred via USB or LAN, or wifi connection. The user cannot only follow up the production over the cutting list that is displayed on the touch panel but also can print the labels for the cut pieces. Ino Machinery produces accurate and precise machines for the “aluminum industry.”

Product Properties

Electronic measuring system added to the side of single-head cutting machines.The 7″ touch panel automatically goes to the dimensions entered, the profiles are precisely cut to the right size based on these dimensions.It is possible for the operator to enter the dimensions manually or to transfer a cut list prepared in the office to the machine via LAN cable, USB or Wi-Fi.After the profiles are cut, the barcode can also be pasted via the barcode printer.It can be made from the right or left with feed.By synchronously connecting with the saw, automatic drive cutting can also be done.

Optional Accessories

Directional construction according to the profile feed from the right.

Transfer data via USB.Transmitting data via LAN cable.

Transferring data via Wi-fi.10.

2″ Touch Panel modification.

15.0″ Touch Panel modification.

System powered by rack thread and pinion.

Automatic profile feeding feature by working synchronously with the saw machine.

Related Products

Display AllALU

PROCESSING

MACHINES

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review