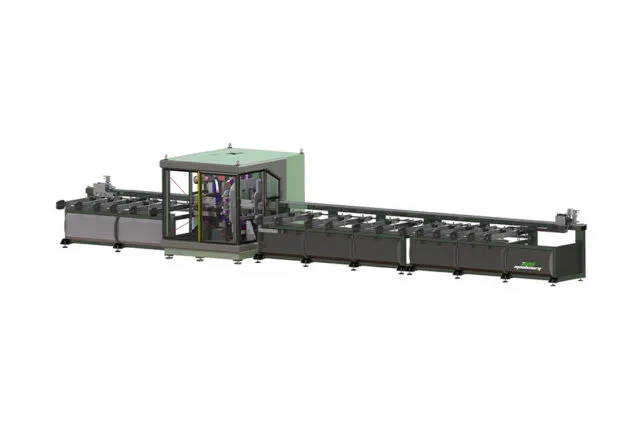

INO ATOM 3+1 AXIS CNC Profile Machining Center

Product Properties

CNC machine with 4-Servo Axis, PLC, 10” HMI TouchPanel, 2.2 kW 18.000 rpm spindle and a tilting table; for processing aluminum profiles, PVC profiles and light alloys within the mentioned processing dimensions via super-user friendly programming interface that needs no operator expertise.

Machine net processing size is 600 mm.,

Machine referance point on the left, manually positioned 1.000 mm.

Machine referance point on the left, positioned by servo control: 1.100 mm. (Optional accessory)

With the optional CNC controlled referance point, placement of the profile is always precise and needs no operator help.

Profile processing capacity: 120X120 mm. Ability to process from 3 surfaces of the profile thanks to table rotation by pneumatic cylinder.

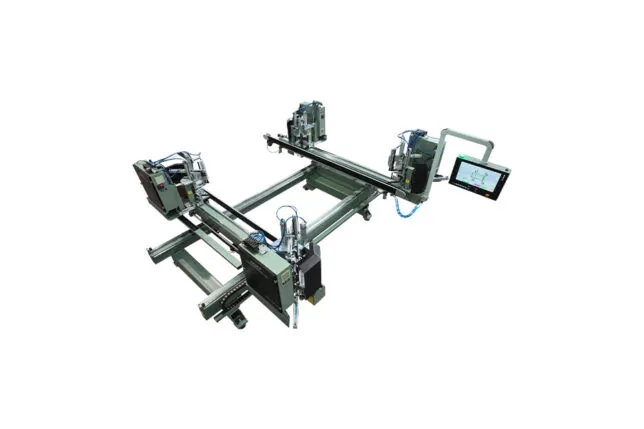

The profile is connected to the machine via pneumatic pistons.

The operator can program the machine by using the super-easy user interface. He will only need to select the type of the operations like circle, rectengle, slot or drill and then enter the processing size on the HMI. The machine is programmed to carry out all the operations with the fastest feed rate according to they type of the profile.

The machine is customized especially for Windows and Doors profiles.

It processes lock cases, handles and cylinders, water slots , barrels etc. Thanks to the high frequency 18.000 rpm motor and pulse mist coolant unit.

Machining Dimensions

X Axis net processing length: 600 mm.

X Axis manual referance point stroke: 1.000 mm.

X Axis servo controlled referance point stroke: 1.100 mm

Y Axis net processing width: 120 mm.

Z Axis net processing depth: 120 mm.

X Axis travelling distance: 650 mm.

Y Axis travelling distance: 360 mm.

Z Axis travelling distance: 290 mm.

Electrical Box and Controller Terminal

The electrical panel is placed inside the body; backside of the machine; easy to reach with a sipmly opening cover. All contactors, relays, 4 servo drivers, PLC, spindle inverter are placed inside this cabinet.

Start, stop, clamp and emergency buttons are placed next to the machine.

User interface 10” touchpanel HMI with multi-language support.

Standard Equipment

PLC Control system and 10” HMI.

4 servo motors and drivers.

2.2 kW 18,000 rpm spindle motor with air cooling.

3 kW spindle inverter with 0-18.000 rpm speed adjustment.

Standard 10 mm. router bit and collet.

Automatic cooling of the profile with spray lubrication unit – pulse mist coolant.

Profile clamping group with two horizontal pistons.

Manual profile referance point 1.000 mm stroke.

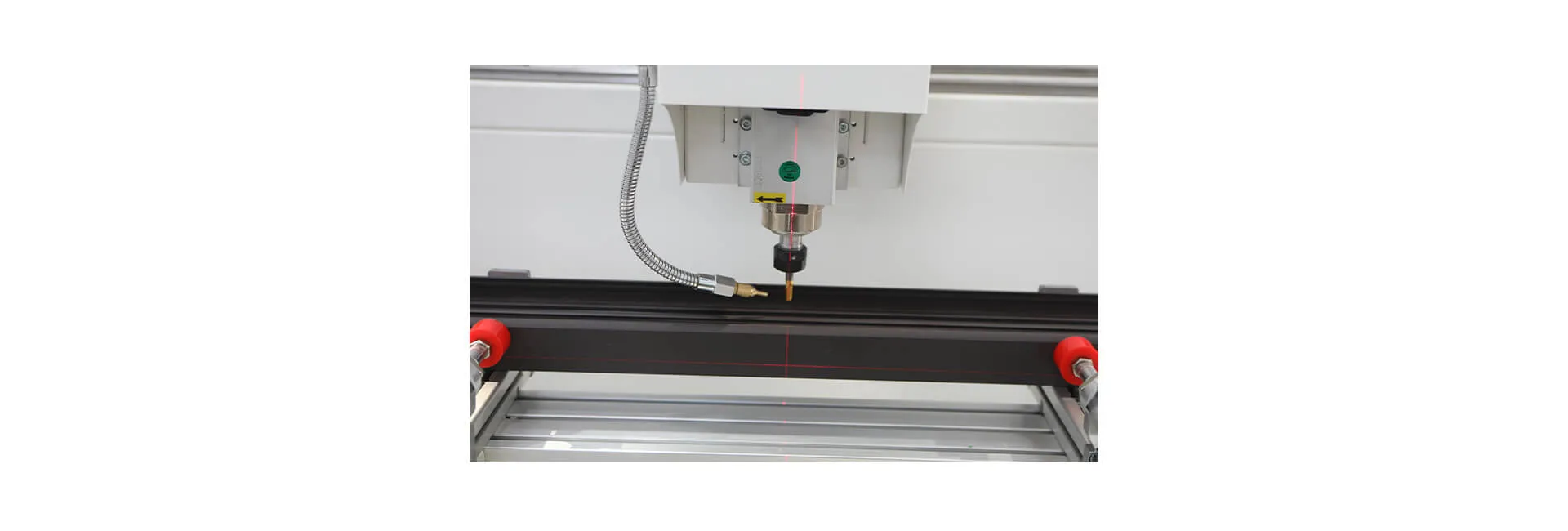

Laser indicator for the central allignment of the profile.

Product Reviews

There is no review yet.

Add a Review