INO AS 490 Automatic Cutting Saw

Product Properties

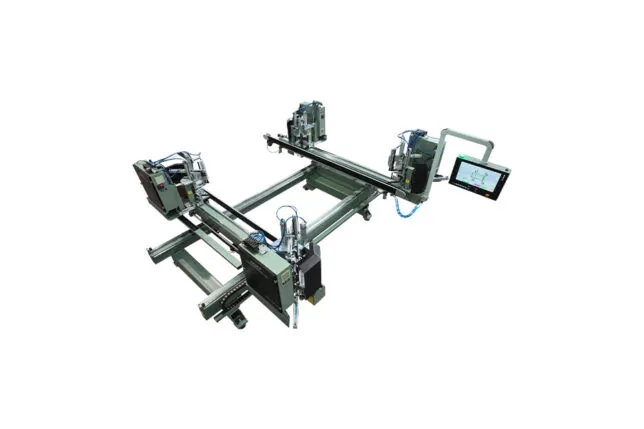

500 mm. automatic single head saw with auto-feed mechanism to cut aluminium corner cleats automatically.

The machine is designed mostly for windows and doors companies.

The sawblade is coming from down to up without any vibration thanks to the hydro-pneumatic piston.

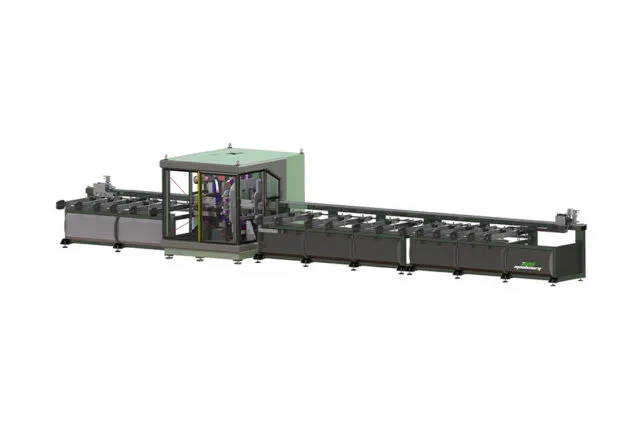

The 6 meter profiles bars are automatically-feeded inside the cutting section with a mechanism working on screw mill and servo motor.

The machine’s cutting accuracy is 0.1 mm.

There is a special clamping hood on the sawing section that clamps both the profile and the cut piece at the same time for perfect grip. This hood also helps the machine to extract the swarf coming out from the cut profile.

Profile Machining Software

The machine is controlled via PLC and a touch panel of 7″.

The cutting dimension and the number of pieces are entered to the machine by using this controller interface that is available in 8 different languages.

It is possible to enter a cutting-list to the machine with the number of cuts and with different dimensions.

Main Body

Electrowelded steel structure normalized with thermal treatment.

The main body of the machine is processed in 5 Axis CNC cteel machining center.

All the body is painted with powder coating. Mostly all the mechanical pieces are die-casted and machined in our own cnc machining centers.

During the design period our design team prioritize the operators’ ease of use and ergonomy of the machines in the first place.

We don’t only use steel and aluminium in the mechanical structure; but we also use fiberglass casted pieces to decrease the weight of the machining bridge and give the machine a more esthetic look.

Electrical Box and Controller Terminal

The electrics box is welded at the back of the machine body.

The controller terminal is also connected on the machine and it is movable according to the ease of use.

The operator can reach all the buttons, the touchpanel and the profile from the same place he stands.

Related Products

Display AllALU

PROCESSING

MACHINES

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review