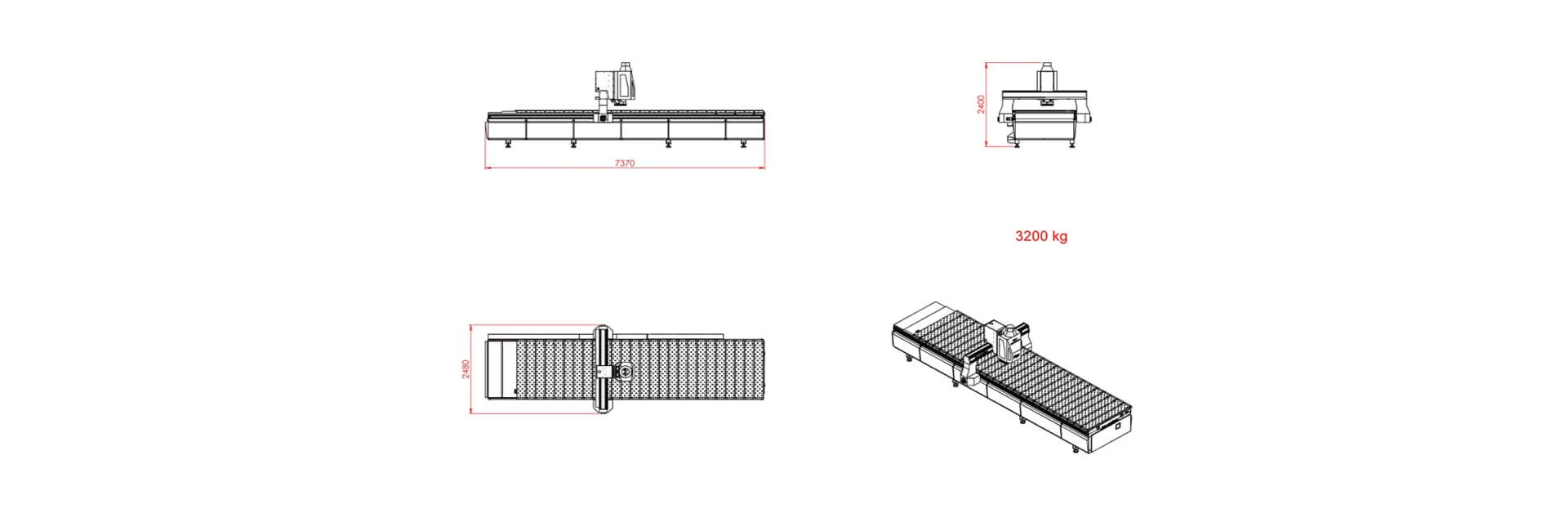

INO XT 1665 Double Station CNC Panel Machining Center

Product Properties

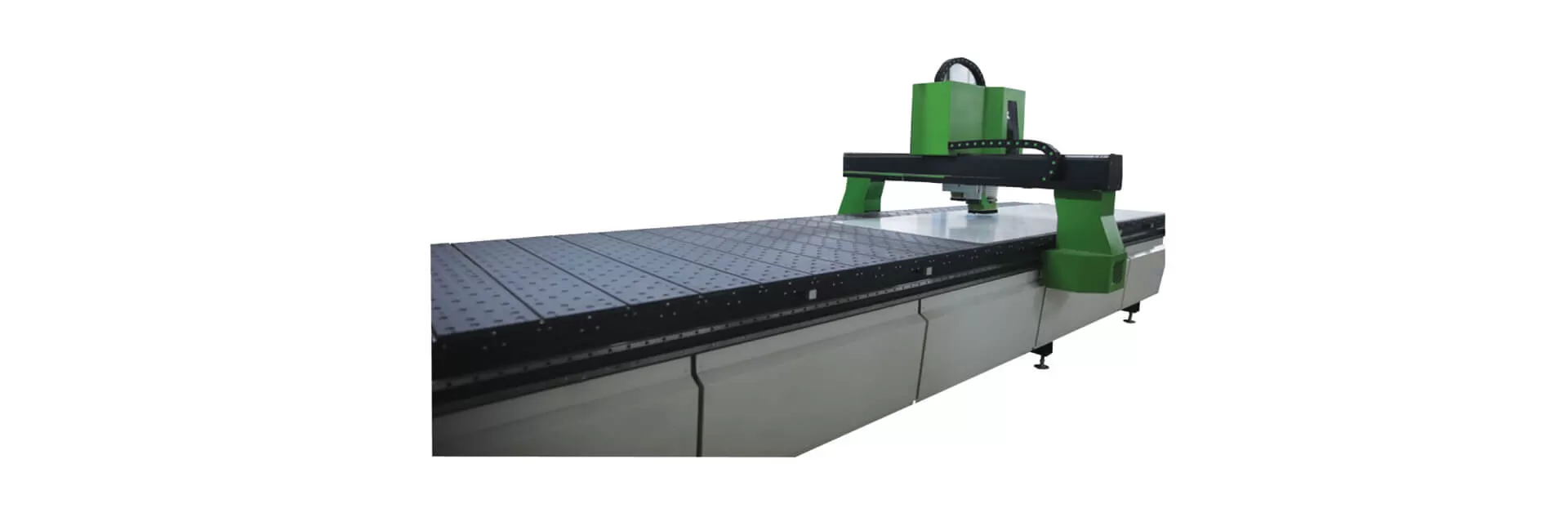

It is a CNC panel machining center that can work in double stations equipped with vacuum table and milling head.The bridge system carrying the milling head moves with two geared servo motors at two heads and moves with an accuracy of 0.1 mm. / 1m.2 panels with a size of 1.600 X 3.200 mm are placed on the machine and processed in double station logic.While the machine is processing one of the panels, loading or unloading can be performed at the other station.

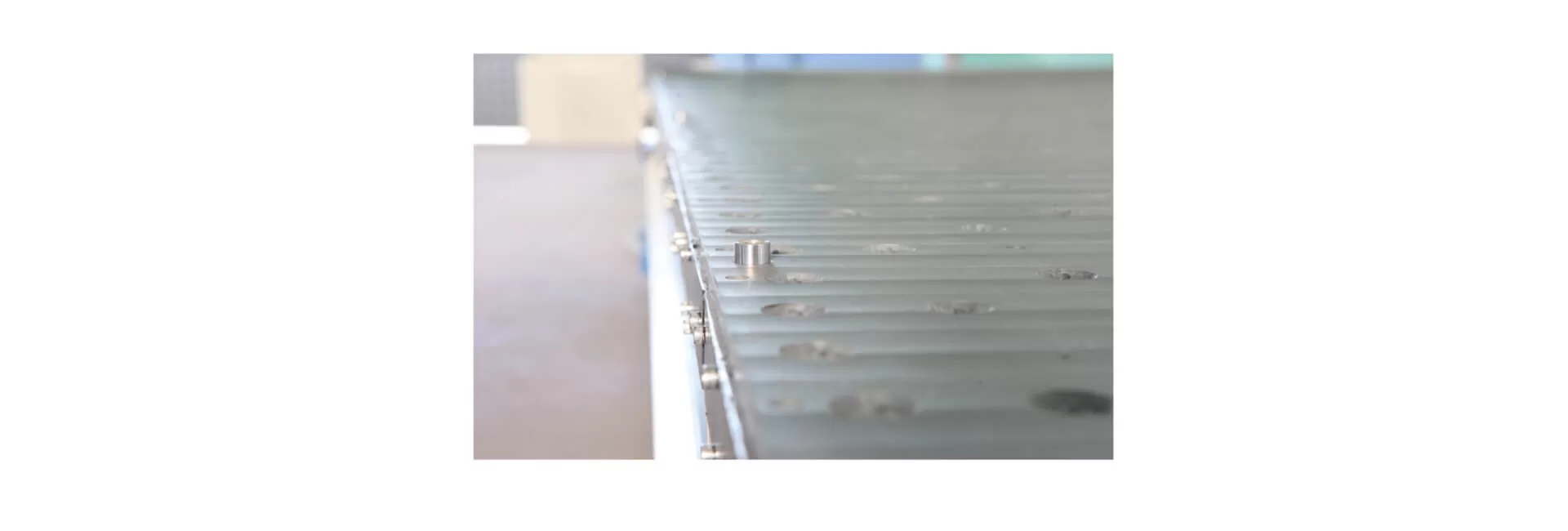

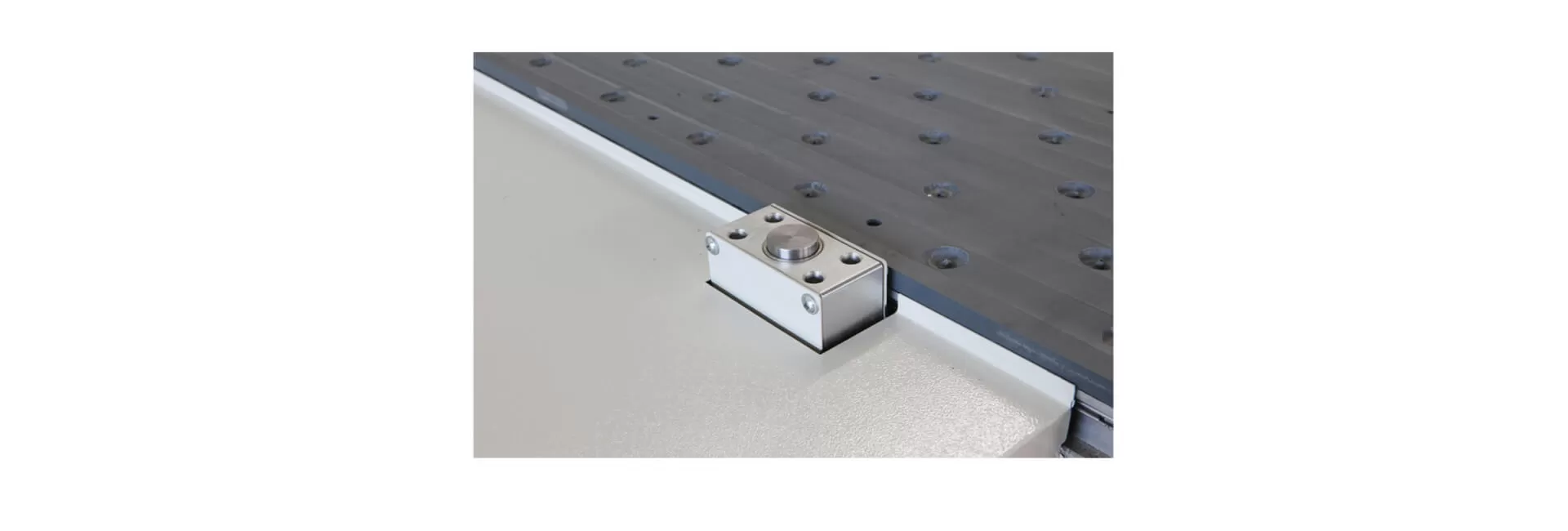

In models with a double spindle working principle, the milling motors work sequentially, and after one of them has finished jointing and finishing his work, he performs the second head cutting operations.Materials that can be machined on the machine: Aluminum Composite Panel, Stainless Steel Composite Panel, Compact laminate panel, Pure Aluminum Panel up to 20 mm wall thickness, Acrylic Panel, MDF, Wood and similar panels.The vacuum table is divided into 8 separate parts and each vacuum chamber can be controlled individually to process small parts in the most precise way.In addition, there is an automatic vacuum opening and closing system in the panel size that is processed on the machine.

The machine uses the SMART TABLE system as a first in the world.This system CNCICALLY controls all vacuum chambers and dabbles according to the size of the panel the manufacturer is processing, according to the speed of operation, according to the thickness of the panel, leaving nothing to the operator’s initiative.

Profile Machining Software

It works with customized software to process the panel.Our program called CamBOX provides great convenience to the drawing staff in the processing of all kinds of plates.

By throwing the DXF drawings of the panels directly into the program and introducing the machining lines on them as different planes, operations such as machining optimization, toolpath optimization, plate optimization and determination of toolpaths can be done through the program.

The dimensions of the wastes in the enterprise can be entered and if necessary, an optimization list can be made with all the wastes.Composite panel, HPL (Compact Laminate) and Aluminum plates related to the construction sector special macros are available.New macros can be created according to customer demand.

Main Body

Welded steel frame normalized by heat treatment.

The main body of the machine is machined in the 5-Axis CNC Steel Machining Center.The entire body is painted with electrostatic powder paint.

Mostly all mechanical parts are machined in our own cnc machining centers or machined on cast material.

During the design process, our design team prioritizes the ease of use and ergonomics of the operators’ machines.

In the mechanical structure, not only steel and aluminum are used; at the same time, fiberglass casting parts are also used to reduce the weight of the processing bridge and give the machine a more aesthetic appearance.

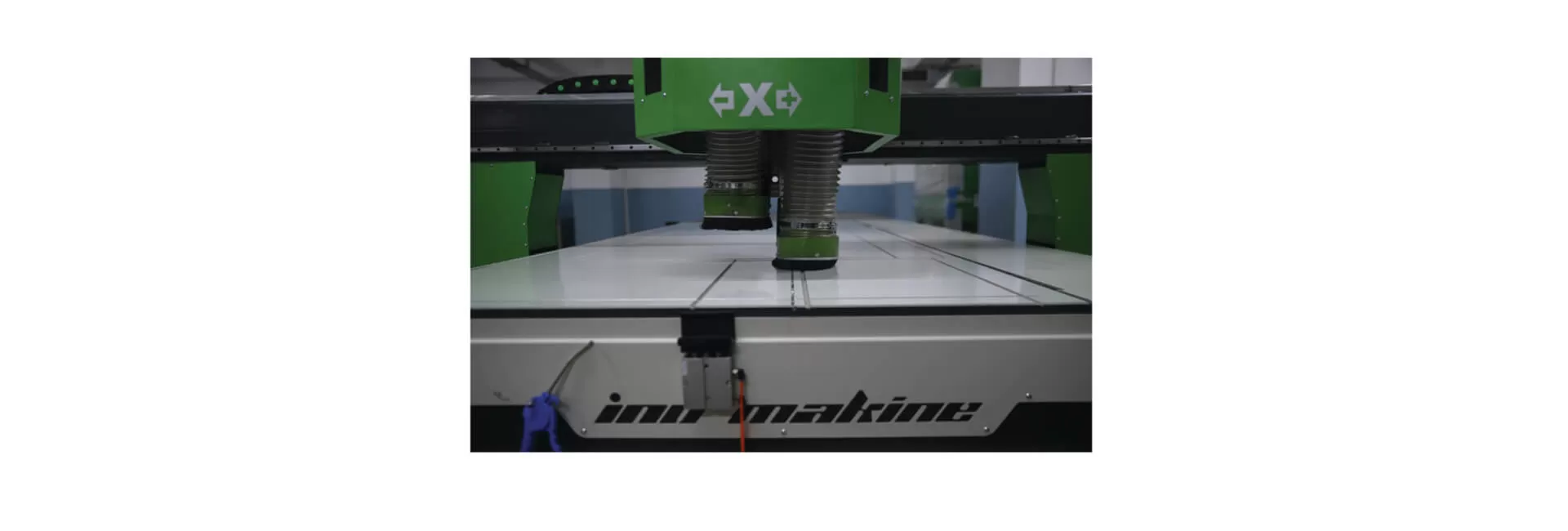

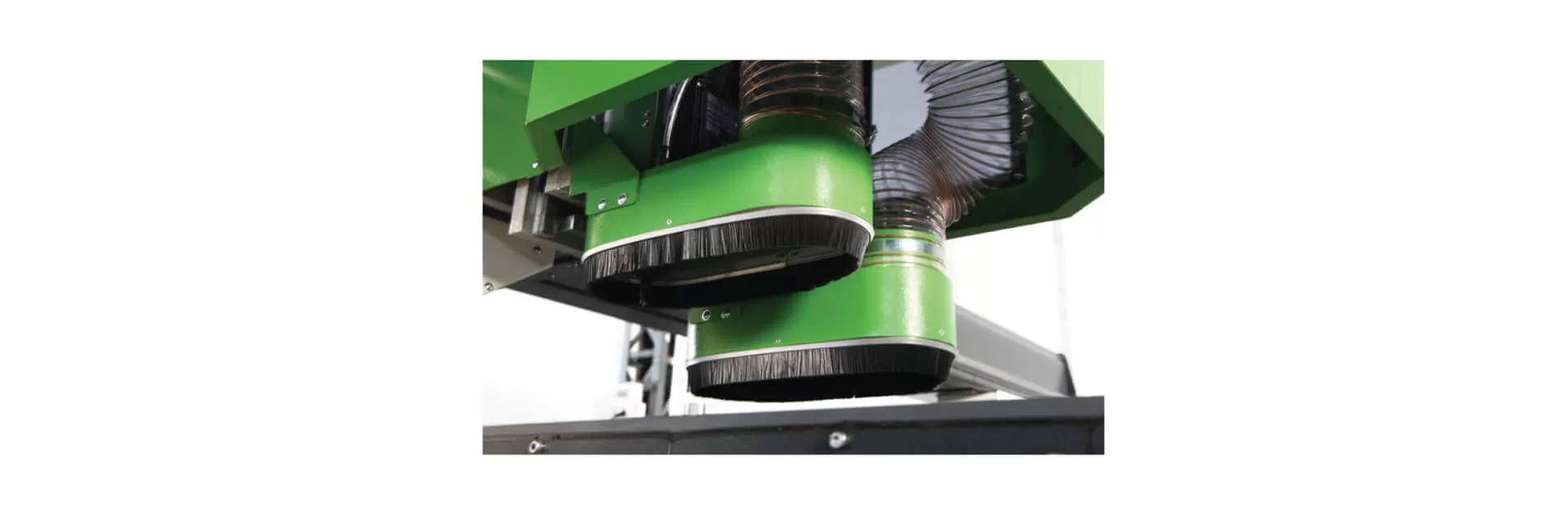

Spindles

The Double Spindle versions are equipped with two spindle heads with an ER-32 tool holder with a power of 5.5 kW and 18,000 rpm, and the two tools work sequentially.In composite panel machining, the first tool first does the joint opening process and the second team does the sizing work with milling.

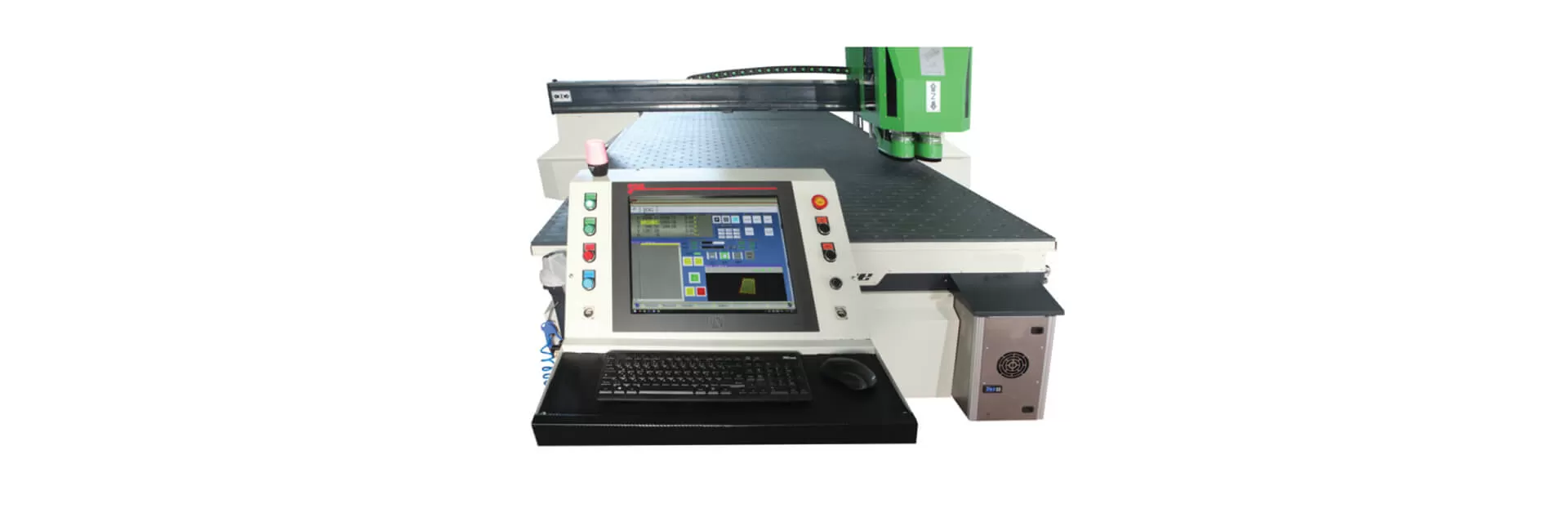

Electrical Box and Controller Terminal

The electrical panel is located inside the machine body.

Forced fan cooled as standard, optionally cooled by air conditioning for hot climates.

The control terminal is also designed as an integrated unit on the machine, it is connected to the electrical panel by an internal cable.

Thanks to this positioning, the operator controls the machine while loading the pneal.

On the control terminal, there is a 10″ touch screen, machine on/off button, buttons that move the axes +/- , potentiometer buttons that manage the machine progress rate, as well as a keyboard and mouse.

Axis features

The X-axis moves on the crave teeth, pinion and linear skids, with the help of two Servo Motors and Planetary gearboxes.Axis speed is 80 m./min.With the help of Y-axis Servo Motor and Planetary reducer, the craveli movement on the tread, pinion and linear slides.Axis speed 65 m./minThe Z-axis moves with a 1/1 reduction coupling on a 25-roll 25 screw shaft.Axis speed 25 m./min.

Standard Equipment

Automatic opening and closing of vacuum zones according to the size of the sheet to be machined with the help of CNC control.

Eight pneumatic reference points.

305 m3 vacuum pump.4.0 kw 18,000 rpm ER-25 two spindles.

Lubrication of axis bearings.

3D CAD-CAM software.

10″ Touch screen.

Product Reviews

There is no review yet.

Add a Review