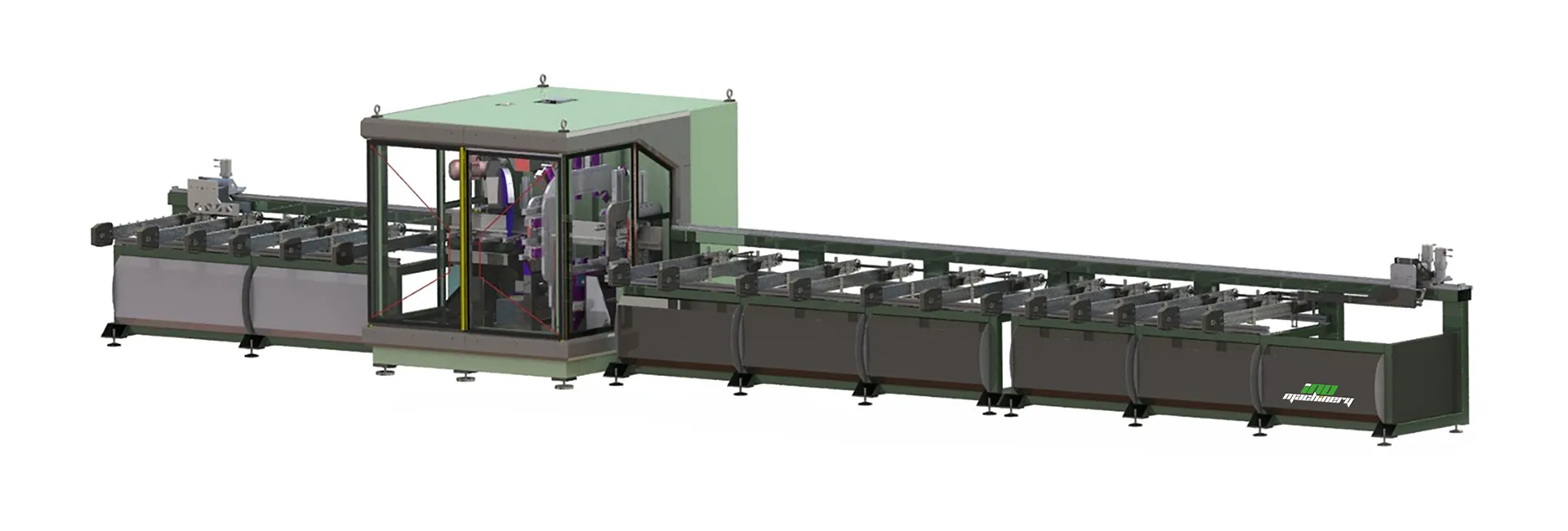

Ino BARCELONA – CNC PVC Profile Cutting and Machining Center

PVC

9 AXISBARCELONA CNC PVC Profile Machining Center, standing out in PVC window fabrication with advanced machining software and a servo motor system.

9-Axis.

600mm. Sawblade.

300-1500 deg Rotation.

10 Tools on the Tool-Ring.

6.500mm. Feeding Size.

10 Profile Loading Station.

3.0m. Off-Loading Station on Belts.

Dust Extraction Roller Conveyor.

21” Touch-Panel PC.

Product Properties

The BARCELONA CNC PVC Profile Machining Center continues to impress with its comprehensive features:

• Integrated Manufacturing Processes: Bringing together sawing, routing, drilling, and marking processes into one machine enhances both production speed and quality standards, eliminating the need for separate machines.

• High Loading Capacity and Adaptive Gripper: The machine can load up to 10 profiles simultaneously, each with a maximum length of 6500 mm. The servo motor-controlled profile gripper automatically positions itself, accommodating various profile designs and sizes, thus enhancing versatility.

• High-Performance Industrial PC: Featuring a 21” industrial PC running Windows 11, the machine offers an ergonomic design and a user-friendly interface for seamless operation. Its connection via a movable arm adds to convenience.

• Precision Machining with 3-Axis Movement: The machine’s high-quality milling group can move in 3 Axis X-Y-Z directions, facilitating precise operations such as drain slot routing, drilling, and milling. A vertical saw with a 600 mm diameter allows for automatic cutting at angles between 30° to 150°, all controlled by servo motors to ensure high-speed and accurate cutting.

• Automated Transfer and Labeling: After cutting, profiles are automatically transferred to the exit station via the gripper system. Integrated labeling enables seamless production integration with CNC welding and corner cleaning machines.

• Efficient Waste Management: Waste parts generated during milling and cutting are efficiently handled by an automatic inclined conveyor system, transporting them to the waste bin. This system also supports remote service, facilitating problem detection and resolution through internet connection.

• Servo Motor Control: The machine boasts a total of 9 servo motors, with 3 servo axis on the gripper, 3 on the tool ring, 2 on the saw group, and 1 on the offloading, ensuring precise control and movement across various operations. With its advanced CNC controller, machining software, and comprehensive servo motor system, the inoBARCELONA CNC PVC Profile Machining Center stands out as a top-tier solution for PVC window and door fabrication.

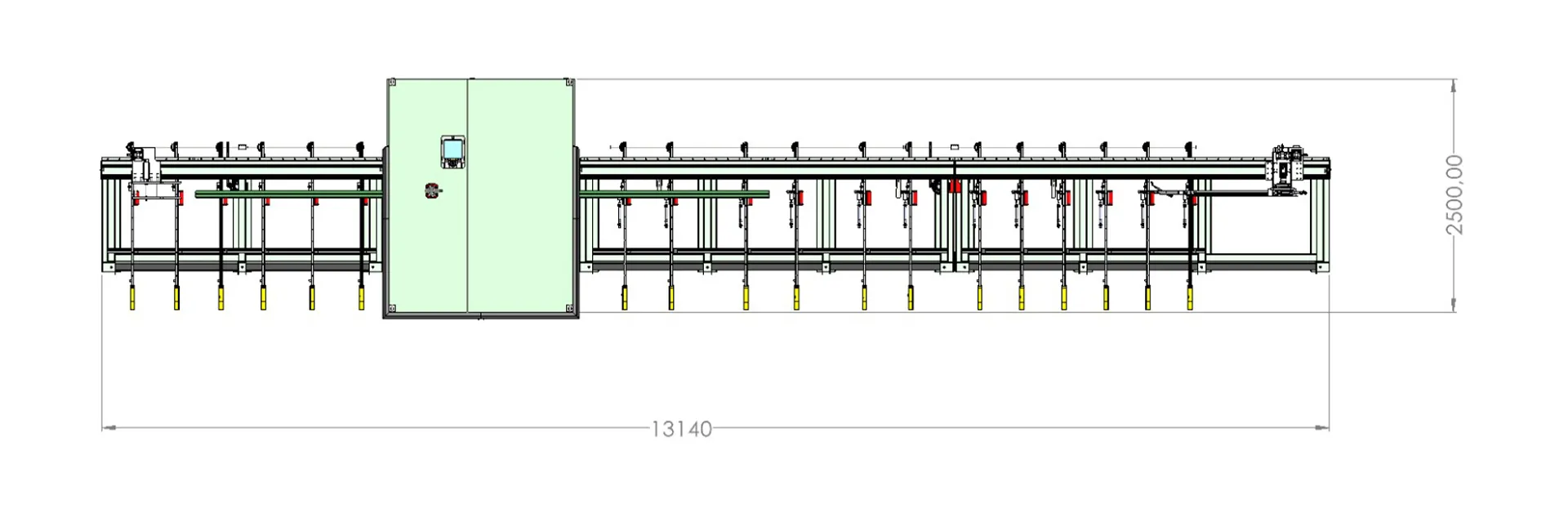

Machining Dimensions

• Saw-blade Diameter: 600 mm.

• Max. Profile Length: 6500 mm.

• Min. Profile Length: 330 mm.

• Max. Raw Profile Length: 6500 mm.

• Min. Raw Profile Length: 500 mm.

• Max. Profile Height: 200 mm (customized for “renovation” profiles)

• Min. Profile Height: 30 mm.

• Max. Profile Width: 200 mm.

• Min. Profile Width: 30 mm.

Main Body

The inoBARCELONA CNC PVC Profile Machining Center is built with robust construction and thoughtful design considerations:

• Electrowelded Steel Structure: The machine’s foundation is an electrowelded steel structure, normalized with thermal treatment, ensuring durability and stability during operation.

• Main Body Machining: The main body of the machine undergoes precision machining in a 5 Axis CNC Steel Machining Center, guaranteeing accuracy and consistency in its design and assembly.

• Powder Coating Finish: To enhance longevity and resistance to wear and tear, the entire body of the machine is coated with powder coating, providing a durable and aesthetic finish.

• High-Quality Mechanical Components: The majority of mechanical components are die-casted and machined in-house using CNC machining centers. This ensures control over quality and allows for precise customization according to design specifications. Emphasis is placed on operator ease of use and ergonomic design during the manufacturing process.

• Diverse Material Usage: While steel and aluminum form the backbone of the mechanical structure, fiberglass casted pieces are also employed to reduce the weight of the machining bridge. This not only enhances the machine’s performance but also contributes to its aesthetic appeal.

Overall, the inoBARCELONA CNC PVC Profile Machining Center is meticulously crafted with a focus on structural integrity, precision engineering, and user-friendly design, making it a reliable and efficient solution for PVC window and door fabrication.

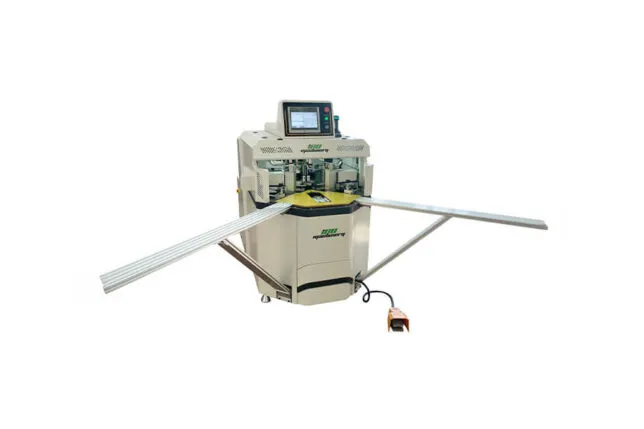

Spindles

The inoBARCELONA CNC PVC Profile Machining Center features powerful spindle and sawing units designed for versatility and precision.

Air Cooling Spindle:

• Power: 0.5 kW

• Speed Range: 0 to 18,000 rpm

• Cooling Method: Air

• Control: Frequency inverter allows for adjustable rpm

This spindle offers flexibility in speed adjustment, allowing for precise control over machining operations. The air cooling mechanism helps maintain optimal temperature during operation, ensuring consistent performance.

Sawing Unit:

• Motor Power: 3 kW

• Speed: 2,800 rpm

• Angular Rotation: Servo-controlled, adjustable from 30° to 150°

The sawing unit is equipped with a powerful motor capable of delivering high torque at a consistent speed. The servo-controlled angular rotation adds to the versatility of the unit, enabling precise cutting at various angles within the specified range.

These units contribute to the inoBARCELONA’s ability to perform a wide range of machining operations with accuracy and efficiency, making it an ideal solution for PVC window and door fabrication.

Electrical Box and Controller Terminal

The inoBARCELONA CNC PVC Profile Machining Center is designed with convenience and flexibility in mind, featuring a separate electrical box and user terminal:

Electrical Box:

• Design: Typically placed at the back of the machine for easy access.

• Mobility: Equipped with wheels for effortless movement.

• Optional A/C Connection: Provision for connecting air conditioning to ensure optimal operating conditions.

User Terminal:

• Design: Positioned separately from the main machine, connected to the electrical box via a 5-meter Ethernet cable.

• Mobility: Mounted on wheels, allowing the operator to move it independently for better accessibility.

Components on User Terminal:

• PC: Enables interface with the machine and controls various operations.

• Keyboard and Mouse: Facilitate input and navigation through software interfaces.

• Handwheel: Provides manual control over machining operations, allowing for precise adjustments.

Button Set:

• On/Off Button: Controls the power supply to the machine.

• Start Button: Initiates machining processes.

• Axis Moving Buttons: Enable manual movement of machine axes for setup and adjustment.

• Feed Rate Regulator: Allows the operator to adjust the feed rate of cutting operations.

• Emergency Button: Provides a quick way to halt machine operations in case of emergencies.

Overall, this setup enhances operator convenience and safety, enabling efficient operation and control of the inoBARCELONA CNC PVC Profile Machining Center.

Related Products

Display AllALU

PROCESSING

MACHINES

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review