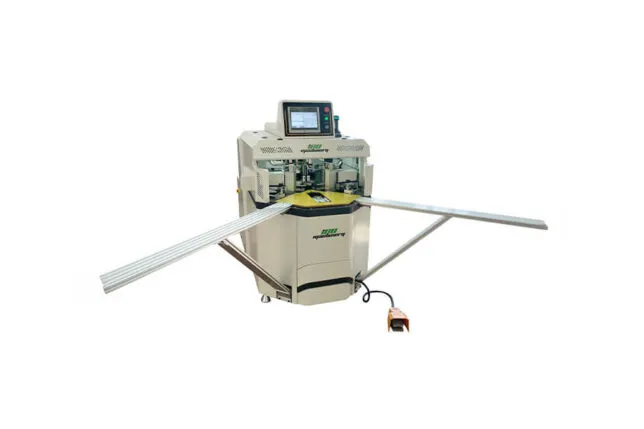

AS 445 Profile Notching Machine

ALU

Double Blade Curtain Wall Profile Notching Machine

Profile notching saw for machining the ends of the curtain wall profiles for cladding purposes in different angles and depths. The machine’s two sawblades can be tilted in +/-45 degrees; the profile loading table can be rotated between 30-150 degrees; the depth and the height of the loading table are also adjusted via handwheels—a perfect solution for end milling of facade profiles.

Product Properties

Wide façade profiles are used to make angled notches on their heads.

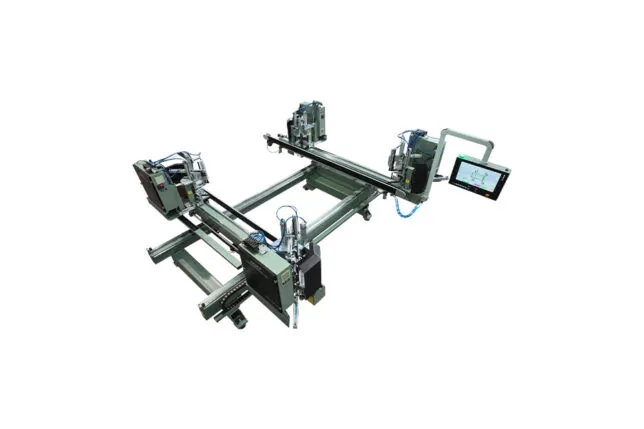

The profile to be renamed is placed on the table that can be opened +/-30 degrees on the vertical axis, two saws positioned perpendicular to each other on a single movable console are angled on the horizontal axis between +/- 45 degrees and the profile head is emptied with the movement of the console.

While the saws and the table can be angled, the table where the profile is placed can be adjusted both height and depth.In this way, a total of 5 different settings are made and notched are made at the desired angle at the beginning of the profile.It is especially suitable for use in winter garden, skylight, twisted facades, panel façade systems and similar works.

Main Body

Welded steel frame normalized by heat treatment.

The main body of the machine is machined in the 5-Axis CNC Steel Machining Center.

The entire body is painted with electrostatic powder paint.

Mostly all mechanical parts are machined in our own cnc machining centers or machined on cast material.

During the design process, our design team prioritizes the ease of use and ergonomics of the operators’ machines.

In the mechanical structure, not only steel and aluminum are used; at the same time, fiberglass casting parts are also used to reduce the weight of the processing bridge and give the machine a more aesthetic appearance.

Related Products

Display AllALU

PROCESSING

MACHINES

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review