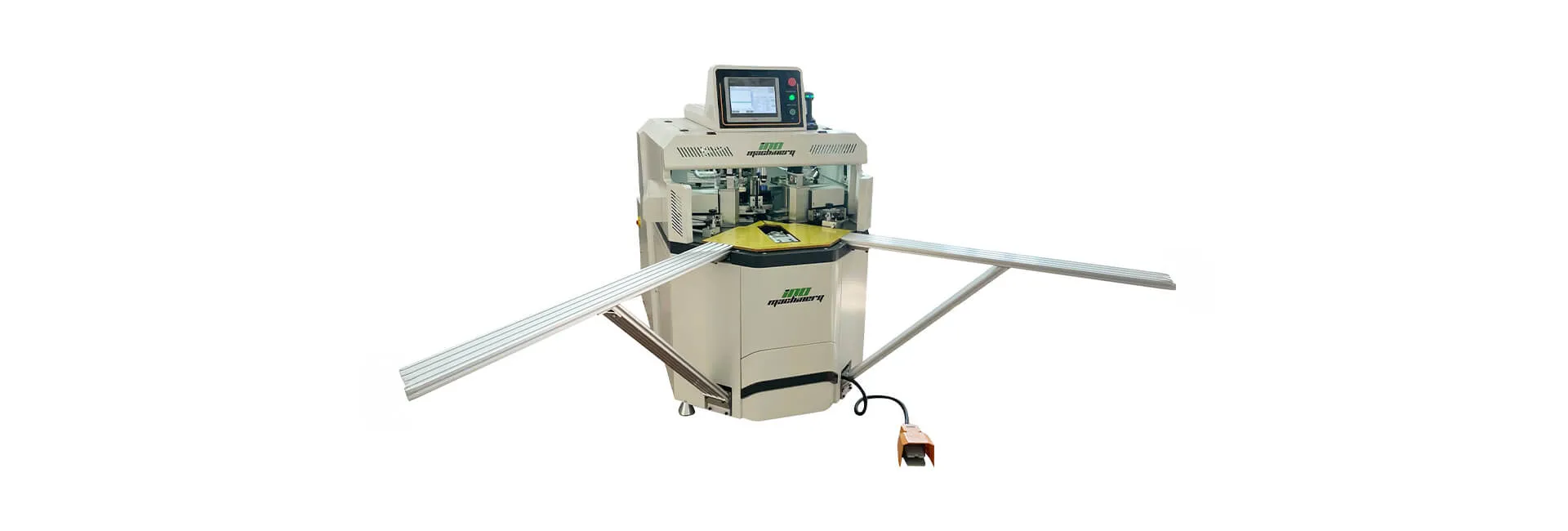

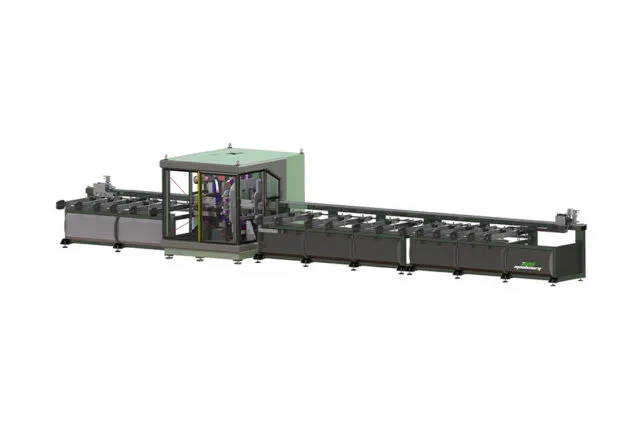

INO HERCULES CNC Corner Crimping Machine

Product Properties

INO HERCULES model aluminum corner crimping machine – 9 Axis CNC controlled with PLC unit, 10″ colored TFT-LED touch screen.

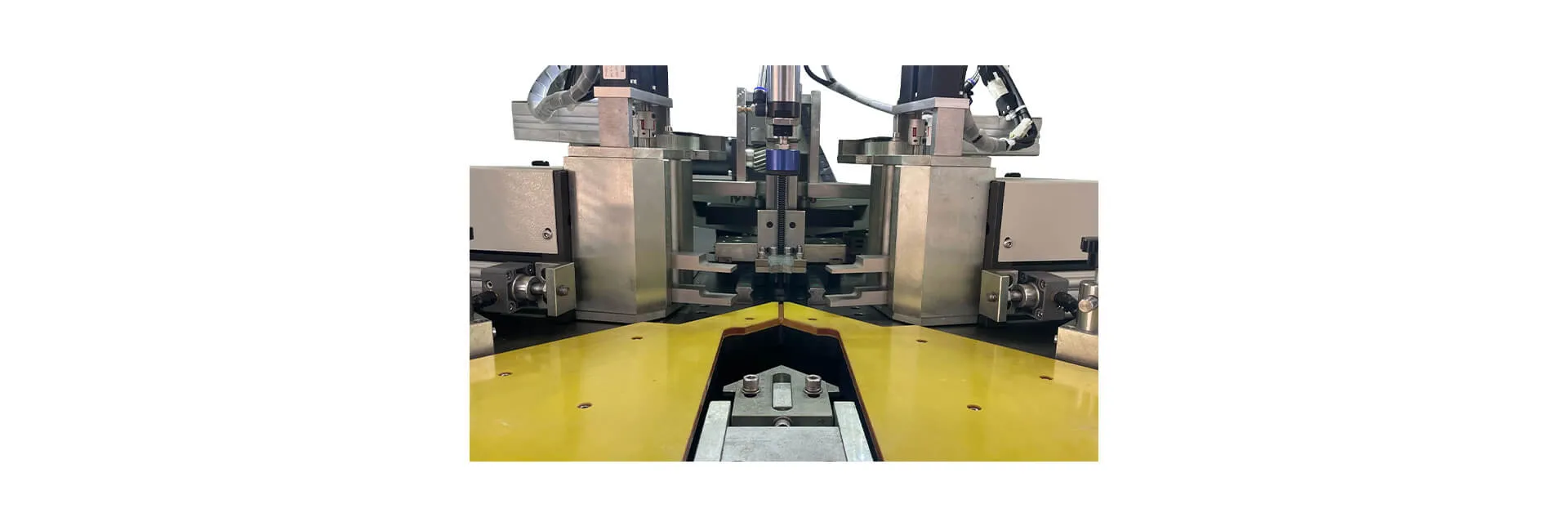

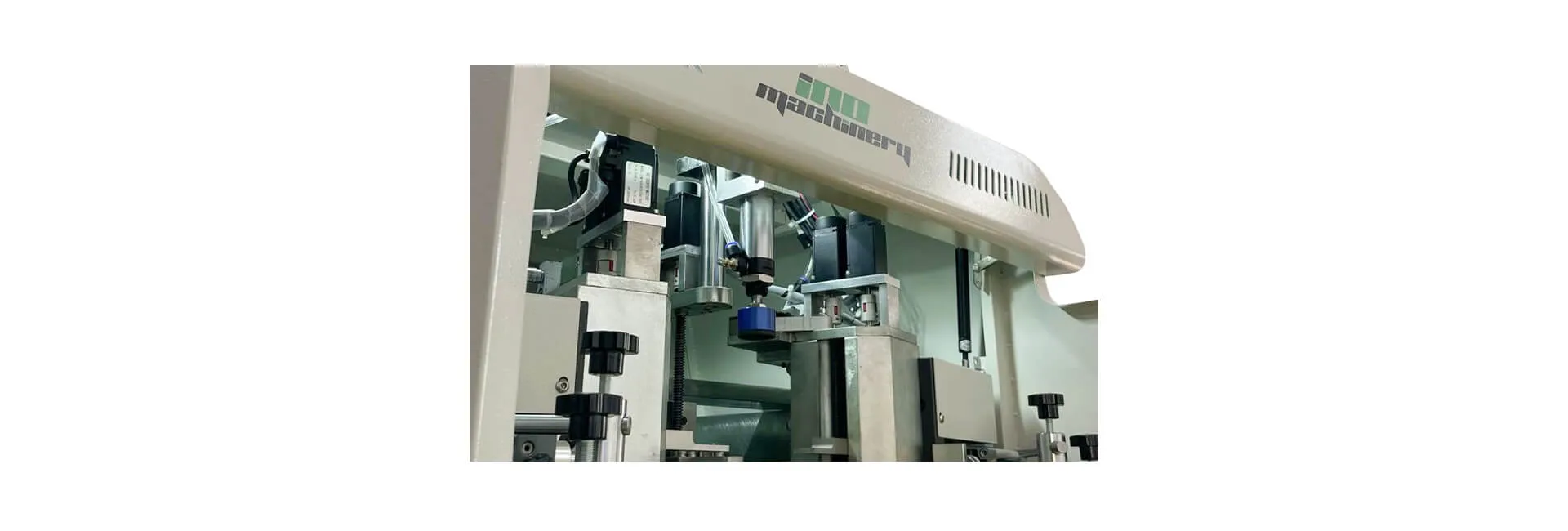

Press heads equipped with 2 universal knives have an automatically adjustable system with CNC control.

The knives move forward to press the corners via servo motors.

Servo pressing process not only guarantees synchronous movement of the pressing heads, thanks to a system driven by a screw shaft, but also performs a very powerful pressing of 150 tons.

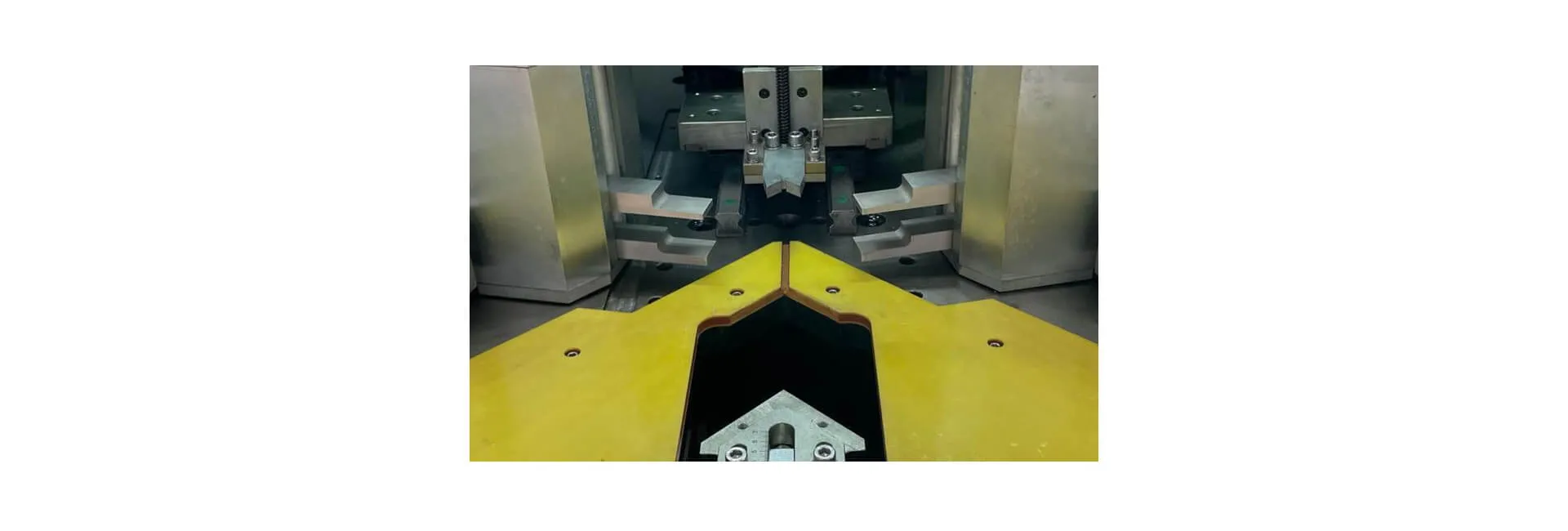

INO HERCULES has a miter stop unit with retractable servo that facilitates the alignment of the frames.

The horizontal, recessed miter stop unit guarantees proper alignment and uniform pressing of the aluminum profiles during pressing.

The backgauge is also servo controlled; for this reason, each blade in the head group equipped with 2 blades can be programmed completely freely to press on different parts of the profile at different times from different heights.

When pressing on the corners, 4 blades can press from different places.

In this way, pressing at different heights on insulated sash profiles or double pressing on unitized systems can be done on this machine without operator intervention.

Side support arms are offered as standard.

2 blades 4/6 mm included as standard

2 pedals for cycle start.

Profile Machining Software

With the HMI screen on the machine, you can adjust the height and width settings of the pressing knives.

You can also save these positions and continue the process.

The number of profile systems to be saved on the memory is 10,000.

You can give a separate name to each profile system and have a special barcode prepared for each.

You can re-load these systems by calling them from the hard disc and scanning their barcodes.

In this way, you will save significant time on labor-work.

Related Products

Display AllALU

PROCESSING

MACHINES

CNC Profile Machining

Ino Machinery; It develops, manufactures and exports modern CNC PROFILE MACHINING CENTERS and similar technologies that can perform machining precision manufacturing works on aluminum profiles.

DiscoverCNC Panel Processing

Our CNC panel machining center models produced with superior INO Machinery R&D technology, with processes such as high precision aluminum composite panel cutting and grouting.

DiscoverCopy Router | End Milling

Our models of Milling machines such as copy milling machine and medium record milling specially designed and developed for the manufacture of aluminum door window and façade Wings.

DiscoverCorner Press

Our corner press machine models used in the corner joining process of aluminum profiles, which guarantee the smooth alignment and blocking of aluminum profiles during pressing.

DiscoverAluminum Profile Cutting Saws

Our automatic single head and double head saw / cutting machine models with the ability to cut horizontal or vertical fixed aluminum profiles.

Discover

Product Reviews

There is no review yet.

Add a Review